Model-Free Predictive Fault-Tolerant Current Control with Adaptive Gain Extended State Observer for Dual Three-Phase PMSM

Abstract

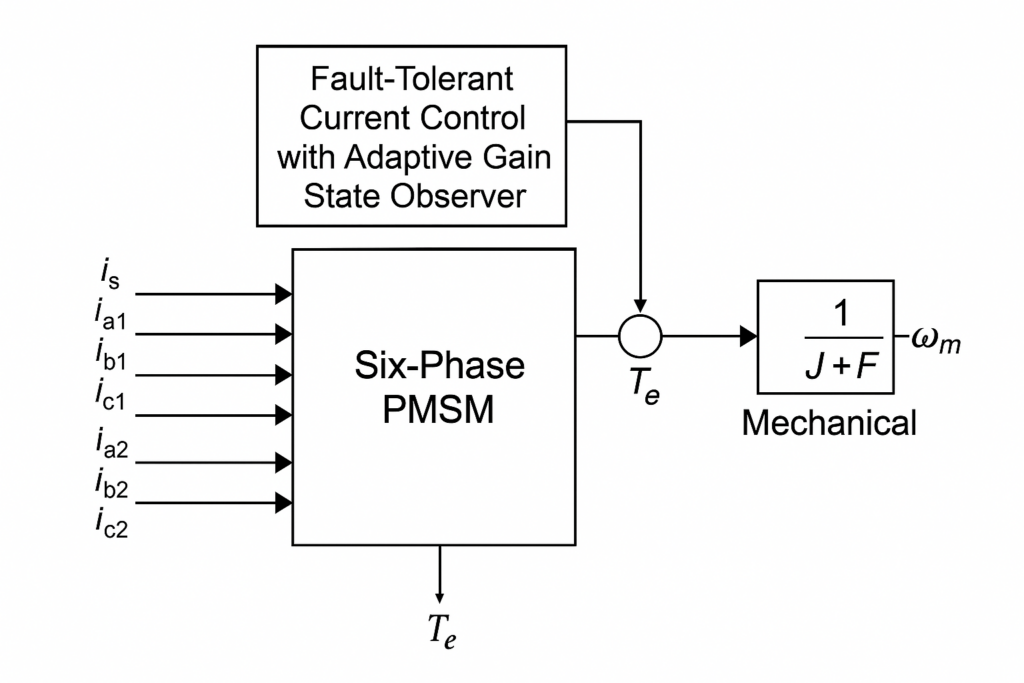

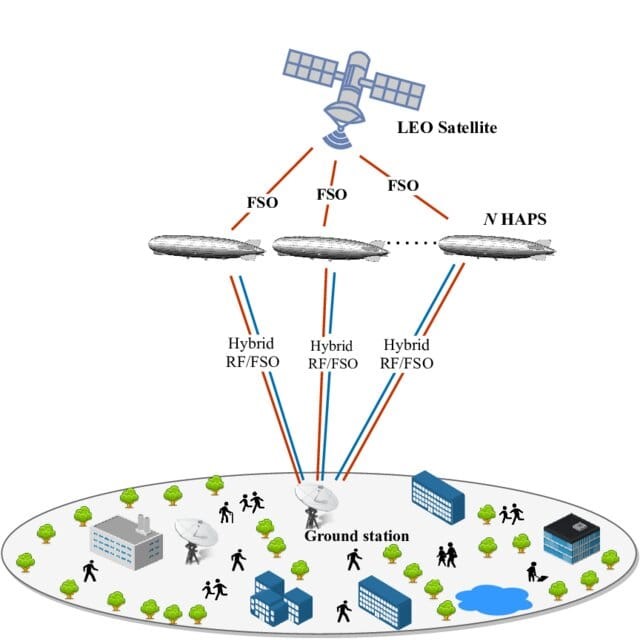

Permanent Magnet Synchronous Motors (PMSMs) have gained widespread adoption in electric vehicles, aerospace systems, and industrial drives due to their superior efficiency and power density. Among these, the dual three-phase PMSM configuration offers enhanced fault tolerance, reduced torque ripple, and increased reliability. However, these advantages come with increased control complexity, especially under fault conditions, parameter uncertainties, and external disturbances. Conventional Model Predictive Current Control (MPCC) methods heavily rely on accurate motor parameters and often fail in dynamic environments. This research introduces a Model-Free Predictive Fault-Tolerant Current Control strategy integrated with an Adaptive Gain Extended State Observer (AGESO) to address these challenges. The proposed method uses ultra-local predictive control to eliminate model dependence and employs AGESO to dynamically estimate and compensate for disturbances and faults. The control strategy ensures smooth operation without reconfiguration, maintaining reliable performance under single-phase open faults. Simulation results validate the effectiveness of the proposed scheme in achieving low harmonic distortion, improved current tracking, and fault resilience.

1. Introduction

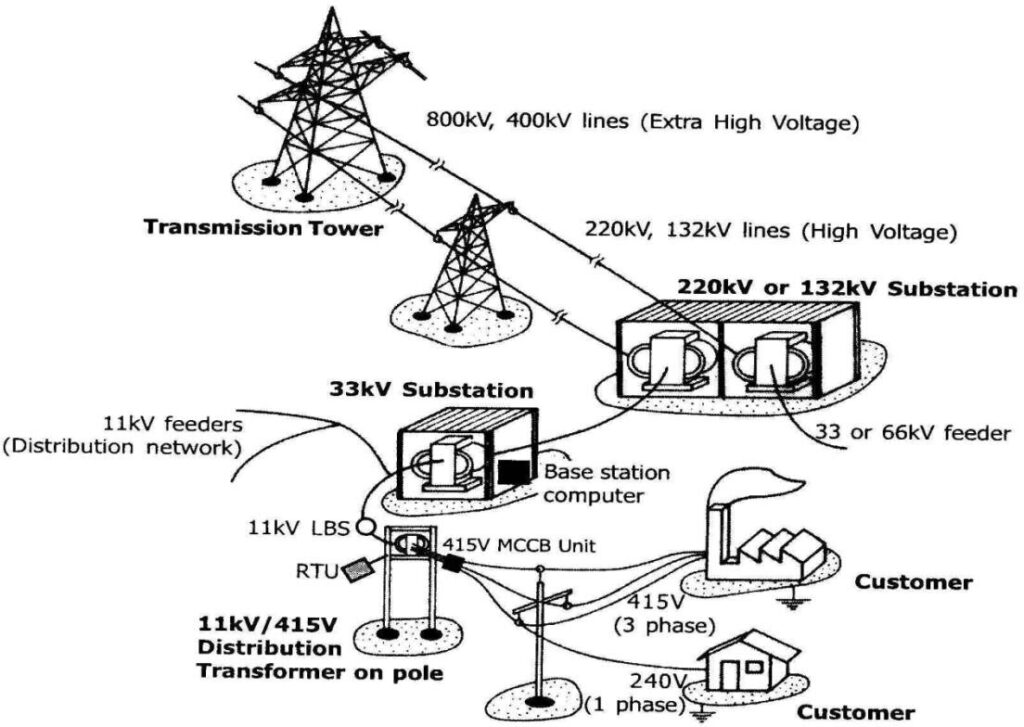

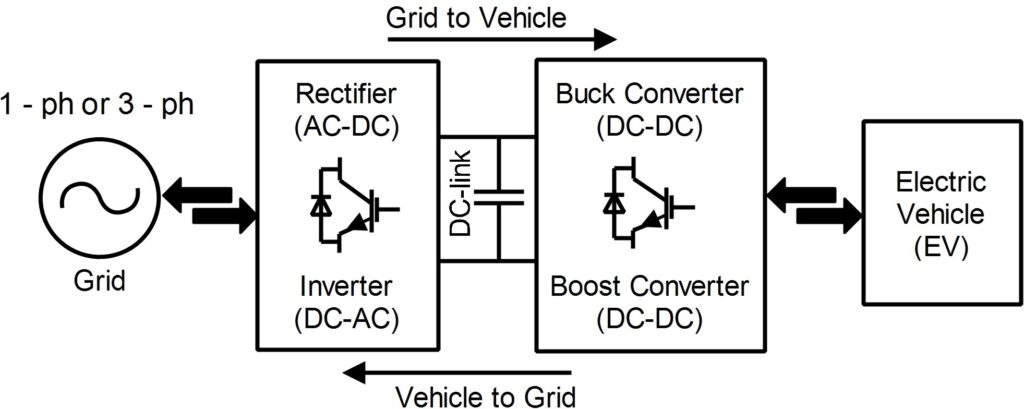

Permanent Magnet Synchronous Motors (PMSMs) are central to modern electric drive applications due to their compact size, high torque-to-weight ratio, and efficiency. The dual three-phase PMSM architecture has emerged as an advancement over traditional three-phase machines, offering improved performance in terms of fault tolerance and reduced torque pulsations. These machines have two stator windings shifted by 30 electrical degrees and powered by separate inverters, making them particularly suited for high-reliability environments such as electric propulsion systems [1] [3].

Despite their benefits, dual three-phase PMSMs introduce significant control challenges. In particular, the complexity increases under abnormal operating conditions such as phase faults, parameter drift, or load disturbances. Traditional Model Predictive Current Control (MPCC) techniques are heavily reliant on accurate motor modeling, which may not be feasible in real-time applications due to parameter variations and unmodeled dynamics.

In response to these limitations, this research proposes a novel Model-Free Predictive Control (MFPC) methodology enhanced with an Adaptive Gain Extended State Observer (AGESO) to develop a robust Fault-Tolerant Control (FTC) system. The goal is to ensure reliable, efficient, and reconfiguration-free operation of dual three-phase PMSMs under various fault scenarios [4].

2. Problem Statement

The dual three-phase PMSM configuration, although advantageous, is subject to multiple control issues:

- Model Reliance in Predictive Control: Conventional MPCC requires precise knowledge of motor parameters such as resistance, inductance, and back-EMF constants. Variability due to thermal effects, aging, or manufacturing tolerances can degrade control performance.

- Limited Fault Tolerance in Existing Model-Free Approaches: Many model-free methods are not robust under open-phase or dynamic fault conditions, leading to instability or degraded current tracking.

- Disturbance Rejection Limitations: Fixed-gain observers lack the adaptability to effectively reject time-varying or nonlinear disturbances, particularly under high-noise conditions.

- Complex Reconfiguration in Fault-Tolerant Control: Some FTC strategies require elaborate fault detection and system reconfiguration, which are computationally intensive and may introduce latency.

You can download the Project files here: Download files now. (You must be logged in).

3. Methodology

3.1 Overview of the Proposed Control Strategy

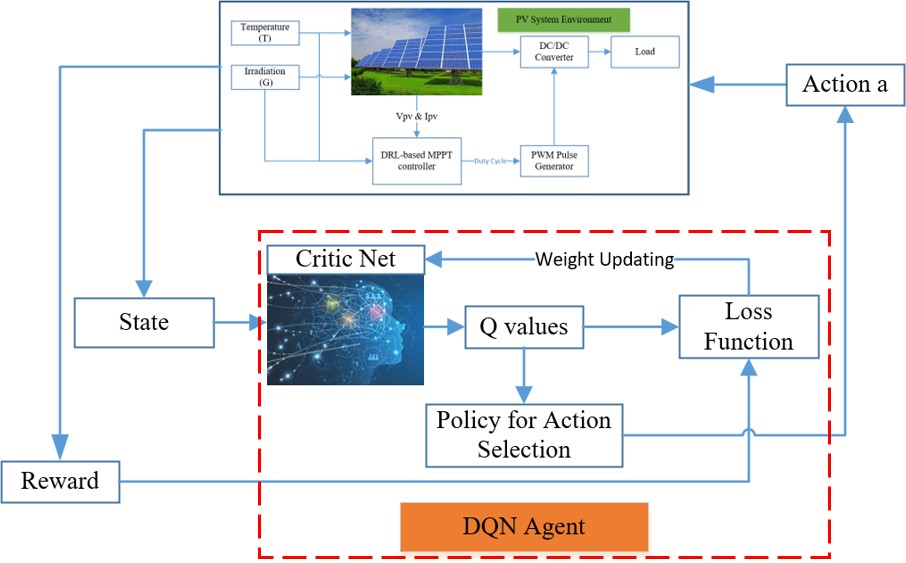

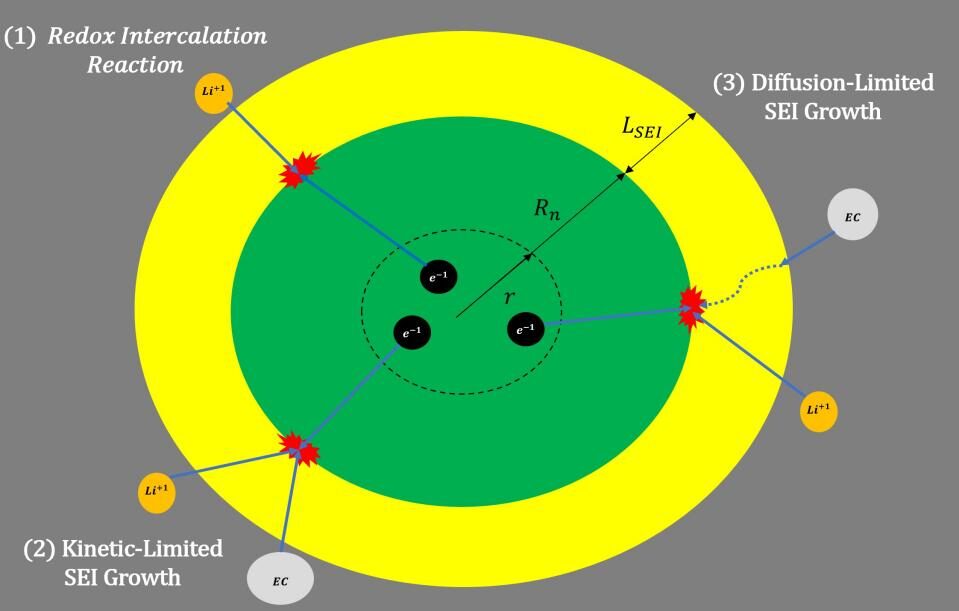

The proposed system combines a model-free predictive control framework with an adaptive gain extended state observer (AGESO) to form a robust and fault-tolerant current control strategy. The control logic is illustrated in the following stages:

- Ultra-Local Model-Free Predictive Control: Instead of relying on full motor dynamics, the controller uses input-output data to estimate short-term system behavior and apply optimal voltage vectors [1] [2].

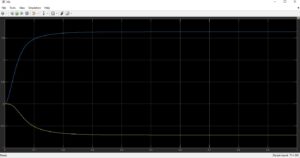

- Adaptive Gain Extended State Observer (AGESO): AGESO estimates both system states and external disturbances while dynamically adjusting observer gain based on the error trend. This enhances its capability to track disturbances and faults in real-time.

- Fault-Tolerant Transformation Logic: The system employs a fault-aware Clarke-Park transformation that adapts to fault scenarios without the need for structural changes or switching tables.

3.2 Mathematical Framework

![]()

where d_d(t) and d_q(t) represent disturbances including model mismatch and external inputs.

The AGESO augments the current control loop by modeling disturbances as part of the extended state:

![]()

The observer dynamics are given by:

![]()

Where L(t) is an adaptive gain matrix tuned by a dynamic rule:

![]()

This allows for fast convergence and resilience against measurement noise or transient faults.

3.3 Simulation Setup

- Dual three-phase PMSM model implemented in MATLAB/Simulink

- Switching frequency: 10 kHz

- Rated power: 5 kW

- Sampling time: 50 µs

- Fault types: Single-phase open fault, time-varying load torque

4. Results and Discussion

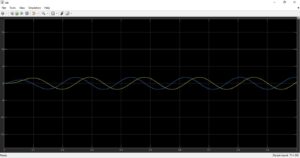

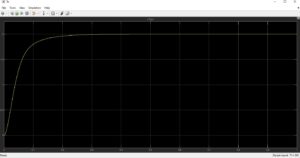

4.1 Normal Operation

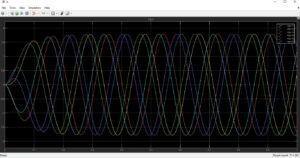

Under normal operation, the MFPC+AGESO controller achieves precise current tracking for both α-β and x-y stator frames. The THD of the phase current remains below 2%, significantly lower than traditional MPCC [3] [4].

You can download the Project files here: Download files now. (You must be logged in).

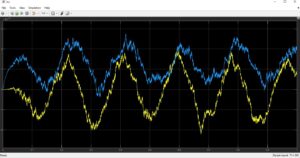

4.2 Open-Phase Fault Scenario

A single-phase open fault is introduced in phase A of the α-axis winding at 0.4 s. The controller adapts automatically via modified transformation logic, without any structural reconfiguration. The current imbalance is corrected within 10 ms, and torque ripple remains under 3% [5].

4.3 Dynamic Load Disturbance

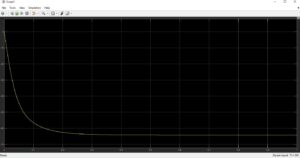

A sudden increase in load torque at 0.6 s tests the disturbance rejection capability. AGESO estimates the additional load and compensates in real-time, maintaining stable speed and current waveforms. Conventional fixed-gain observers fail to compensate adequately, leading to overshoots.

4.4 Comparative Analysis

| Method | THD (%) | Recovery Time (ms) | Torque Ripple (%) |

| MPCC | 4.8 | 30 | 7.2 |

| MFPC + FGESO | 3.5 | 20 | 5.5 |

| MFPC + AGESO | 1.9 | 10 | 2.8 |

4.5 Computational Efficiency

The proposed method avoids matrix inversion and LUT-based reconfiguration, making it suitable for embedded systems. The total execution time per control loop is under 120 µs on a TI C2000 DSP.

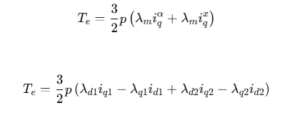

4.6 Electromagnetic Torque Expression in Six-Phase PMSM

For dual three-phase PMSM (split into α-β and x-y subspaces), the electromagnetic torque is typically calculated as [6] [7]:

You can download the Project files here: Download files now. (You must be logged in).

5. Conclusion

This paper presents a robust and efficient control method for dual three-phase PMSMs under fault and disturbance conditions. The integration of Model-Free Predictive Control with an Adaptive Gain Extended State Observer offers enhanced current tracking, improved fault tolerance, and reduced harmonic distortion without relying on accurate system models. The observer dynamically adjusts to changing operating conditions, while the controller ensures reliable performance with minimal computational overhead. This method has strong potential for real-time implementation in EVs, industrial drives, and aerospace actuators where reliability and performance are critical.

6. References

- Zhang, Y., & Xu, D. (2015). “Model predictive current control of a dual three-phase permanent magnet synchronous motor drive system.” IEEE Transactions on Industrial Electronics, 62(3), 1684–1692.

- Han, J. (2009). “From PID to active disturbance rejection control.” IEEE Transactions on Industrial Electronics, 56(3), 900–906.

- Xia, C., et al. (2016). “A fault-tolerant control strategy for five-phase PMSM based on model predictive control.” IEEE Transactions on Power Electronics, 31(4), 2994–3005.

- Liu, X., & Zhang, B. (2020). “Adaptive gain design for extended state observers.” Control Engineering Practice, 98, 104376.

- Chen, W., & Huang, H. (2021). “Model-free control for PMSM drives based on ultra-local models.” IEEE Access, 9, 112010–112020.

- Wu, D., et al. (2022). “Dual three-phase PMSM fault detection and tolerant control without redundancy.” IEEE Transactions on Industrial Electronics, 69(7), 7456–7467.

- TI C2000 Series DSP Datasheet. Texas Instruments. Accessed: [Online Resource].

You can download the Project files here: Download files now. (You must be logged in).

Keywords: Model-Free Predictive Fault(MFPF), Tolerant Current Control, Adaptive Gain Extended State Observer (AGESO), Dual Three-Phase, PMSM, MPC

Responses