Exploring the Evolution of the Industrial Metaverse: Digital Twins and Beyond

In the realm of technological innovation, the Industrial Metaverse has emerged as a revolutionary paradigm, poised to transform industries on a global scale. This convergence of physical and digital realities has swiftly become the focal point of technological discourse, offering unprecedented opportunities and advancements. This article delves into the concept and potential of the Industrial Metaverse, exploring its capacity to usher in a new era of efficiency, innovation, and interactivity. With technologies like digital twins and advanced artificial intelligence at its forefront, the industrial landscape stands on the brink of substantial transformation.

Understanding the Industrial Metaverse

The Industrial Metaverse is a virtual environment that enables real-time collaboration among stakeholders, transcending geographical limitations. Think of it as a digital meeting room enhanced with the power of simulation and advanced visualization.

This virtual space grants users access to digital replicas, known as digital twins, of products, machinery, and entire manufacturing facilities. However, the capabilities of the Industrial Metaverse extend beyond replication. It empowers users to simulate various scenarios, optimizing designs, identifying potential issues, and making data-backed decisions. Imagine testing multiple iterations of a product design or machinery setup without incurring the physical and environmental costs. This transformative impact defines the Industrial Metaverse’s vision for these sectors.

Despite its seemingly futuristic nature, the Industrial Metaverse is already showing signs of massive potential. According to ABI Research, the industrial metaverse market could be worth USD 100 billion by 2030, primarily driven by digital twin technology, extended reality applications, and more. This projection underscores the substantial commercial and operational implications inherent in this transformative technology.

While the consumer metaverse, notably embraced by Mark Zuckerberg and Meta, has dominated headlines, the industrial Metaverse holds transformative potential. Industries like manufacturing and logistics, pioneers of digitalization, are propelling this growth. Their integration of technologies like artificial intelligence (AI), extended reality, and digital twins positions them as leaders in developing the industrial Metaverse. This momentum is expected to catalyze adoption across other industries such as railways, power utilities, and public safety.

Benefits of the Industrial Metaverse

The Industrial Metaverse, as a convergence of virtual and physical worlds, presents numerous possibilities, making it a promising technological advance. Key benefits include:

Rapid Problem Identification and Resolution

This digital universe facilitates swift identification, analysis, and resolution of problems. Potential issues can be preemptively addressed, resulting in significant time and resource savings.

Breakdown of Geographical Barriers

The promise of the Industrial Metaverse lies in a world without distance barriers. Teams from different regions can collaborate seamlessly, fostering a level of global collaboration previously unattainable.

Fostering Innovation

The collaborative environment nurtures innovation, allowing users to delve into the past and project into the future. This aids in understanding processes, solving complex problems, and finding optimal solutions.

Blending Physical and Digital Realities

Beyond breaking geographical barriers, the Industrial Metaverse integrates physical and digital realities through virtual and augmented reality technologies. This intersection empowers industries to reduce costs, operate sustainably, enhance the work experience, and expedite operations by shifting activities into entirely virtual environments.

Enterprises and public sector agencies can experiment with and optimize systems, processes, and infrastructure within digital spaces, addressing potential issues before committing substantial resources to their physical counterparts.

The Industrial Metaverse has the potential to transform industries by promoting collaboration, enhancing problem-solving abilities, reducing costs, and driving innovation. As its potential unfolds, it becomes evident that the Industrial Metaverse is a game-changer for operational technology.

Digital Twins: Pioneers of the Industrial Metaverse

While the full potential of the Industrial Metaverse is still unfolding, one groundbreaking technology within this paradigm is already highly advanced and in daily use: the digital twin.

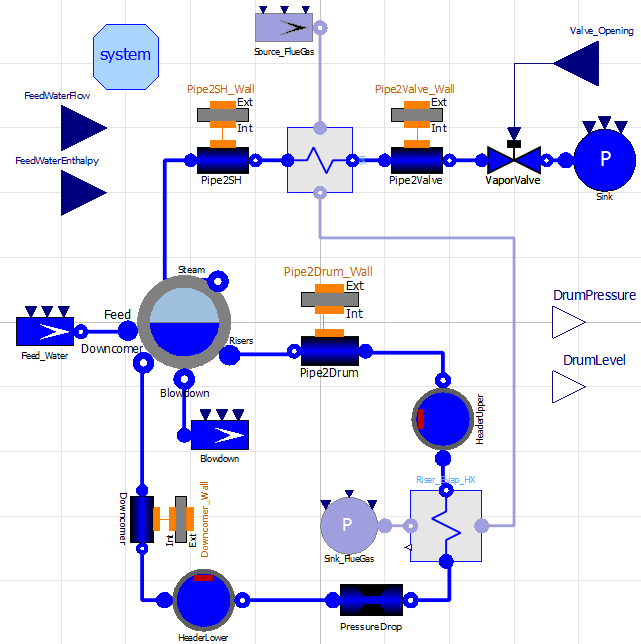

Digital twins are virtual replicas of physical assets or processes that mimic their real-world counterparts’ real-time behavior, performance, and environment. Engineers create comprehensive models infused with data, including inspection and sensor information, to birth a dynamic virtual embodiment – the digital twin.

Siemens’ factory in Nanjing, China, provides a compelling example of digital twin utility. Optimizing construction and detecting potential problems early on, the digital twin played a crucial role in a 200% increase in manufacturing capacity and a 20% rise in productivity.

Akselos, a structural digital twin pioneer, is making waves in the energy industry. Leveraging RB-FEA engineering simulation software, Akselos creates ultra-fast, detailed digital twins of complex structures. This technology enhances safety, reduces downtime, extends asset lifespan, and lowers operational costs.

The full potential of digital twins is realized when deployed across an entire site. Site-wide digital twins enable more informed decisions, optimizing operational efficiency and facilitating proactive maintenance plans.

More information on Digital Twins Technologies.

Expanding the Boundaries of the Industrial Metaverse

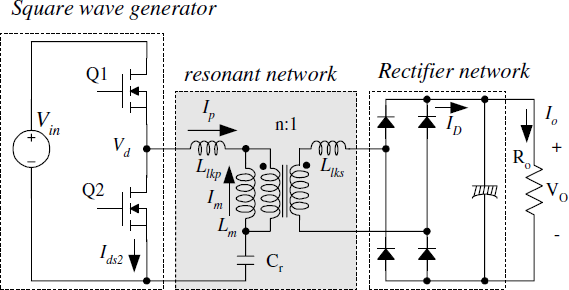

While digital twins are considered the heart of the Industrial Metaverse, they represent just one facet of a larger, rapidly evolving ecosystem. Constructing a fully functional Metaverse requires integrating various technological advancements beyond powerful computing capabilities and faster networks.

The Industrial Metaverse leverages a constellation of cutting-edge technologies, including digital twins, the Internet of Things (IoT), artificial intelligence (AI), cloud and edge computing, blockchain, and extended reality (XR). Infrastructure technologies, such as 5G networks and advanced robotic systems, play pivotal roles in this evolution.

These advancements are not mere futuristic scenarios; they are already materializing. The next decade promises significant breakthroughs, enabling the construction and exploration of the Industrial Metaverse and its optimization.

The IoT, connecting over 16 billion devices worldwide, is expected to triple its reach within this decade. Coupled with the global roll-out of 5G and the development of integrated space-air-ground networks, high-connectivity, low-latency networks will soon be available worldwide. This connectivity ensures seamless, real-time communication within the Industrial Metaverse, irrespective of geographical distance.

Advancements in virtual and augmented reality technology offer more immersive interfaces with the Metaverse. Edge and cloud technology provides fast, reliable computing power to process vast amounts of real-time data generated within the Metaverse. Integration of blockchain and AI enhances security, transparency, and predictive analytics, improving decision-making and operational efficiency.

Conclusion: Embracing the Future

In conclusion, firmly anchored in the concept of digital twins, the Industrial Metaverse is a multi-faceted technological landscape. Its development hinges on harmoniously integrating various technological advancements and innovations.

As we enter an era where physical and virtual realities converge, we stand on the cusp of an industrial revolution like no other. The rise of the Industrial Metaverse signifies transformative changes for industries globally. By leveraging a combination of digital twins, IoT, AI, cloud and edge computing, blockchain, and augmented reality, industries can unlock new efficiencies, drive innovation, and enhance overall operational performance.

The stage is set for the Industrial Metaverse to revolutionize how we work, collaborate, innovate, and grow, unveiling possibilities once beyond our wildest dreams. The journey to realizing its full potential is underway, driven by breakthrough technologies and industries’ relentless pursuit of innovation and excellence.

Responses