Full-Cycle Motor Development — From Concept to Compliance

We design and optimize advanced electric machines for demanding applications – with a focus on performance, safety, and speed at every stage of development.

Solve Your Electric Motor Development Challenges

Struggling with capacity shortages, missed milestones, or incomplete motor designs? Our end-to-end electric motor engineering services help you accelerate development, meet standards, and avoid costly delays.

❌ Unmet motor performance requirements

❌ Unfulfilled project milestones

❌ Incomplete electromagnetic, thermal designs leading to delays in start of production

❌ Risk of drive loss or system destruction

❌ Misalignment with ISO/DO/IEC standards during certification

❌ Human or computational resource scarcity

Accelerate your roadmap and avoid costly rework with proven engineering practices.

Comprehensive Electric Motor Design and Optimization

🔧 Design & Feasibility

- Requirement engineering, system design & breakdown

- Insulation coordination, clearance/creepage distances

- Feasibility study

- Multi-objective design optimization & design review

- Supplier sourcing, RFI/RFQ management, prototyping

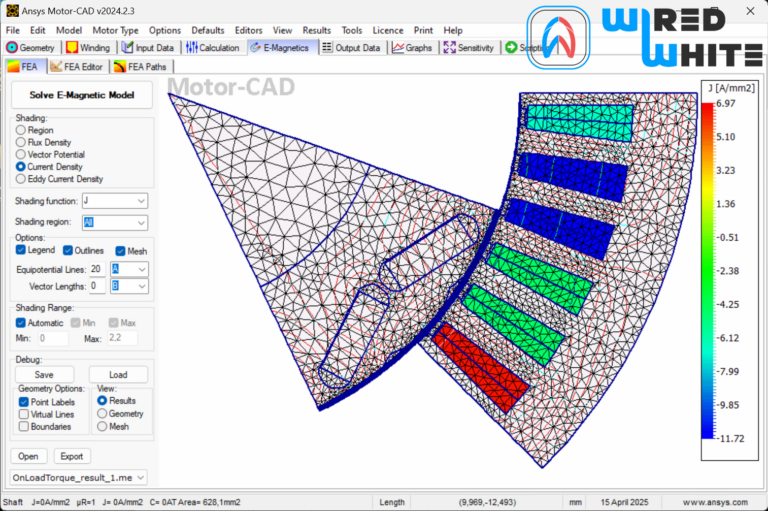

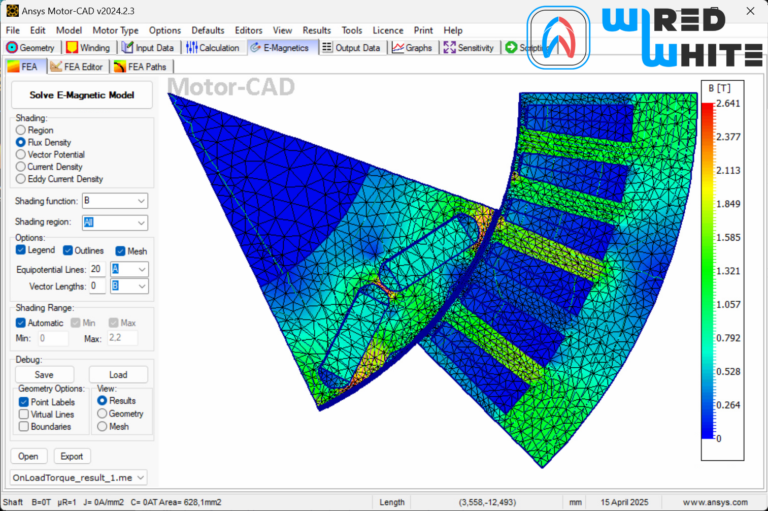

⚡ Electromagnetic Analysis

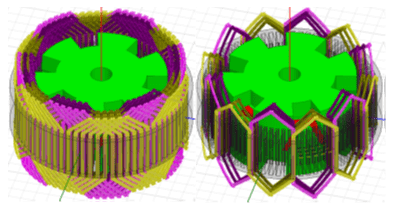

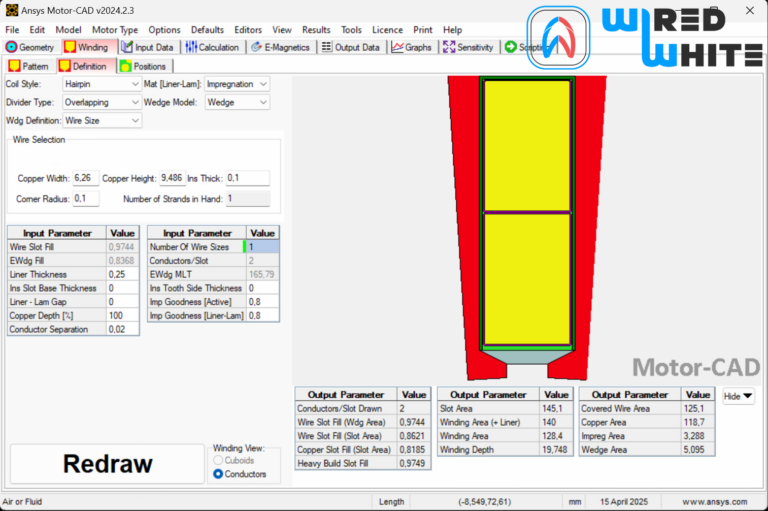

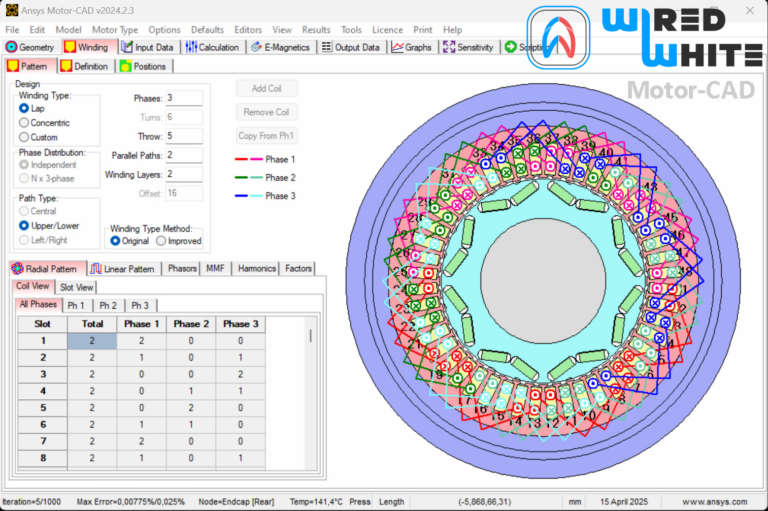

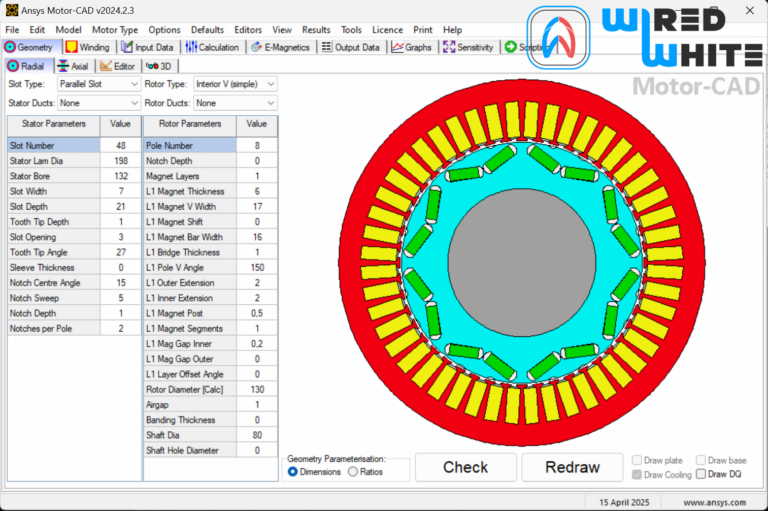

- PMSM (interior & surface mounted magnets), ASM, DC, Reluctance motor design

- Motor Fingerprint, PSI-I maps calculation

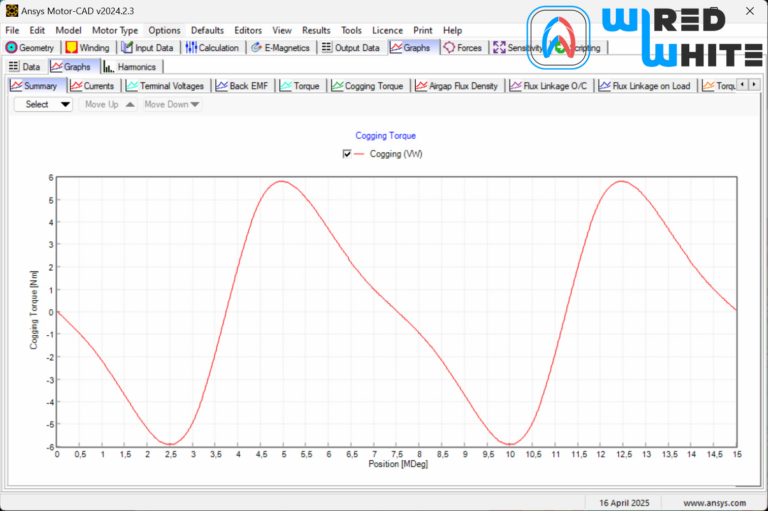

- Cogging torque calculation

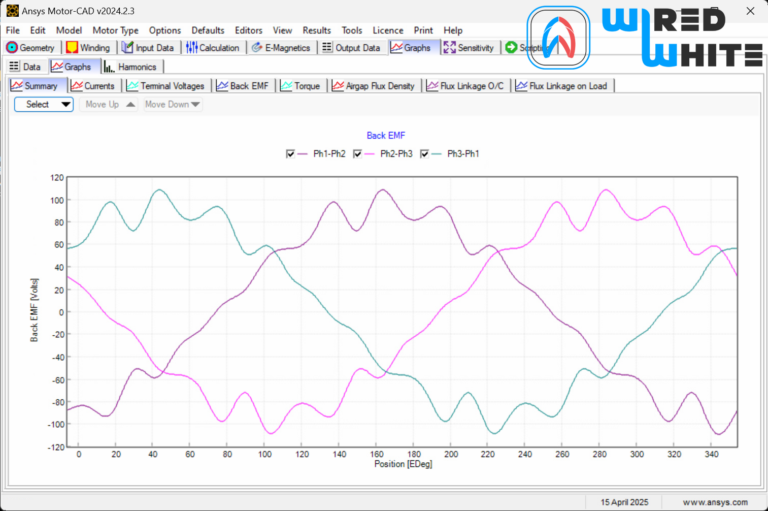

- Cold/hot state Back EMF calculations

- Short-circuit current and torque calculation

- Permanent magnet demagnetization studies

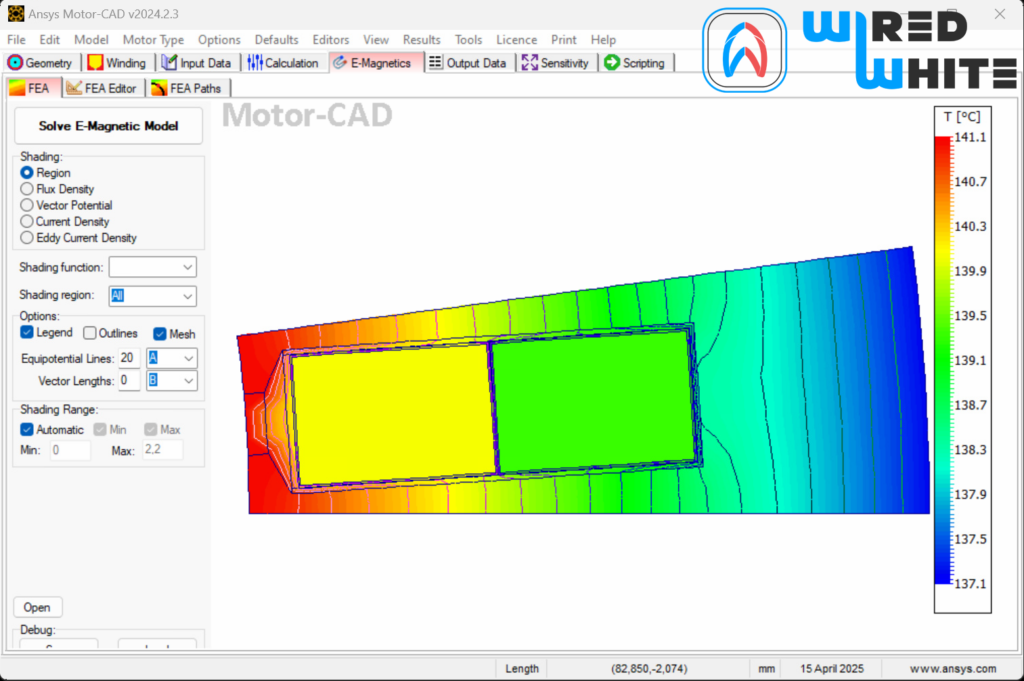

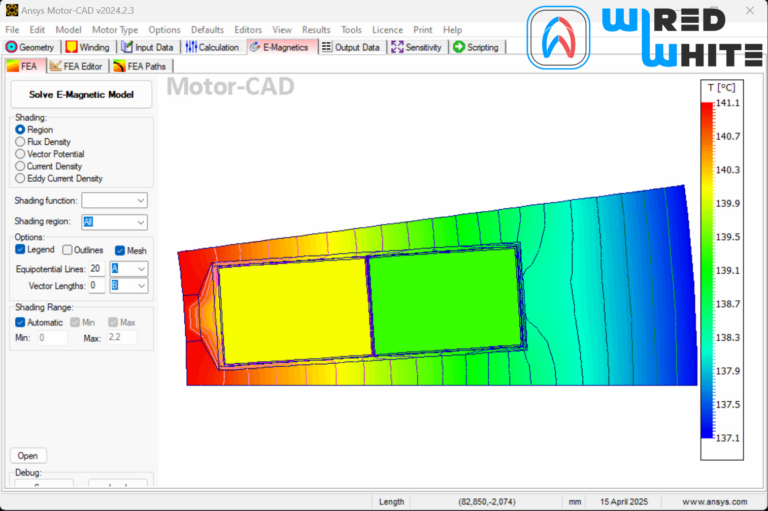

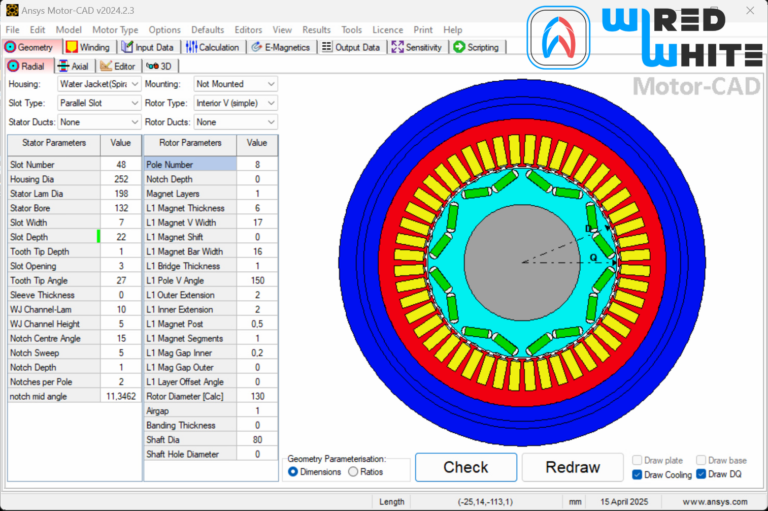

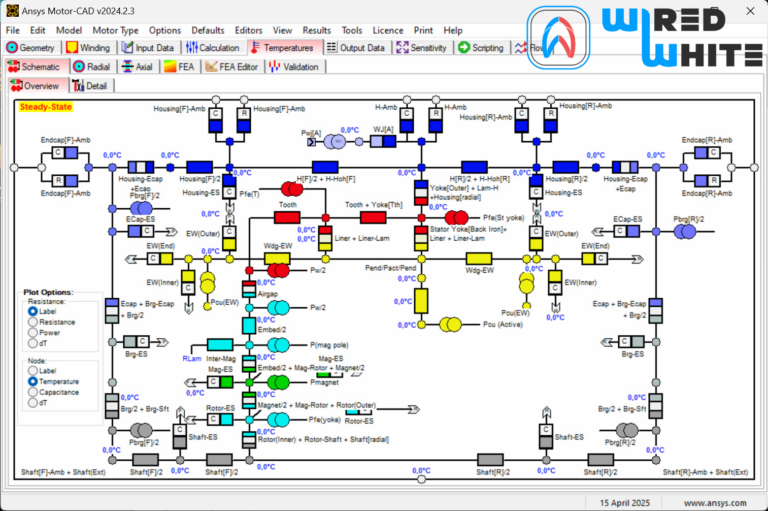

♨️ Thermal Modeling

- Lumped Parameter Thermal Network (LPTN) development

- Torque-speed curve calculation (Rated, Peak, S1/S3 curves)

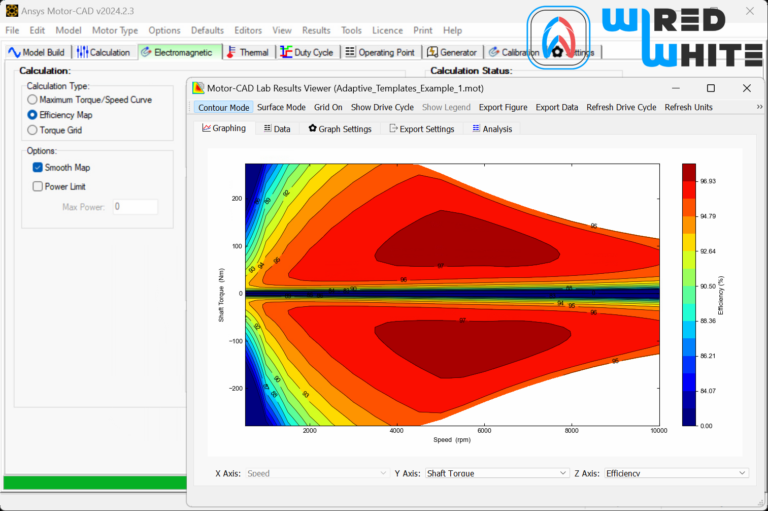

- Efficiency maps creation

- DC, AC, friction, core, magnet, skin effect, proximity effect, eddy current & hysteresis loss analysis

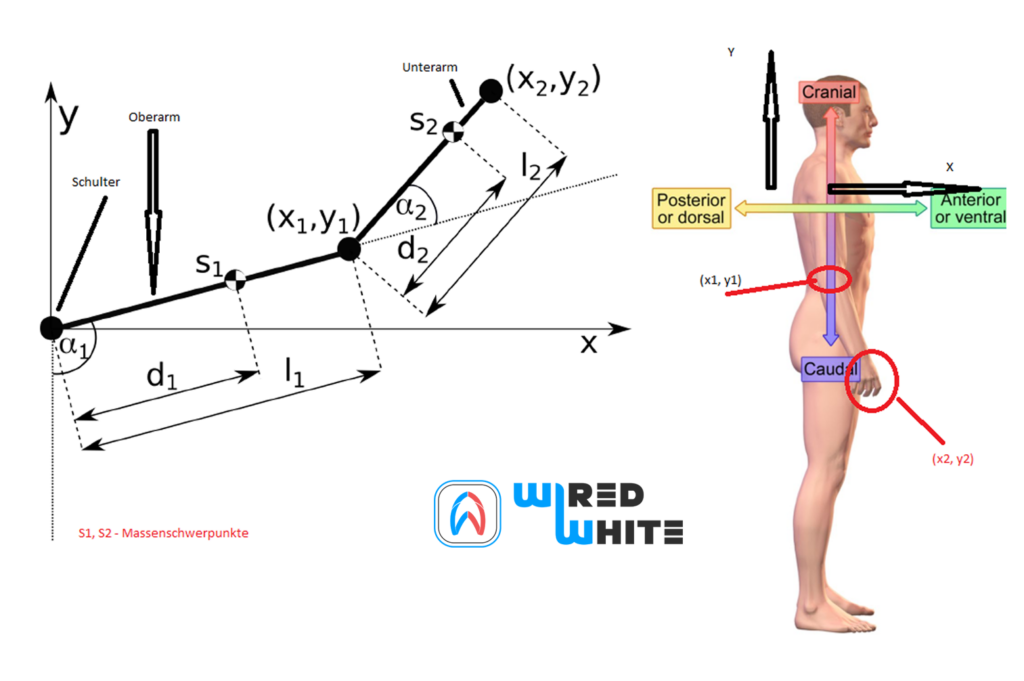

⚙️ Mechanical Analysis

- Modal analysis & NVH simulations (eg in Ansys Workbench)

- System-level stress analysis

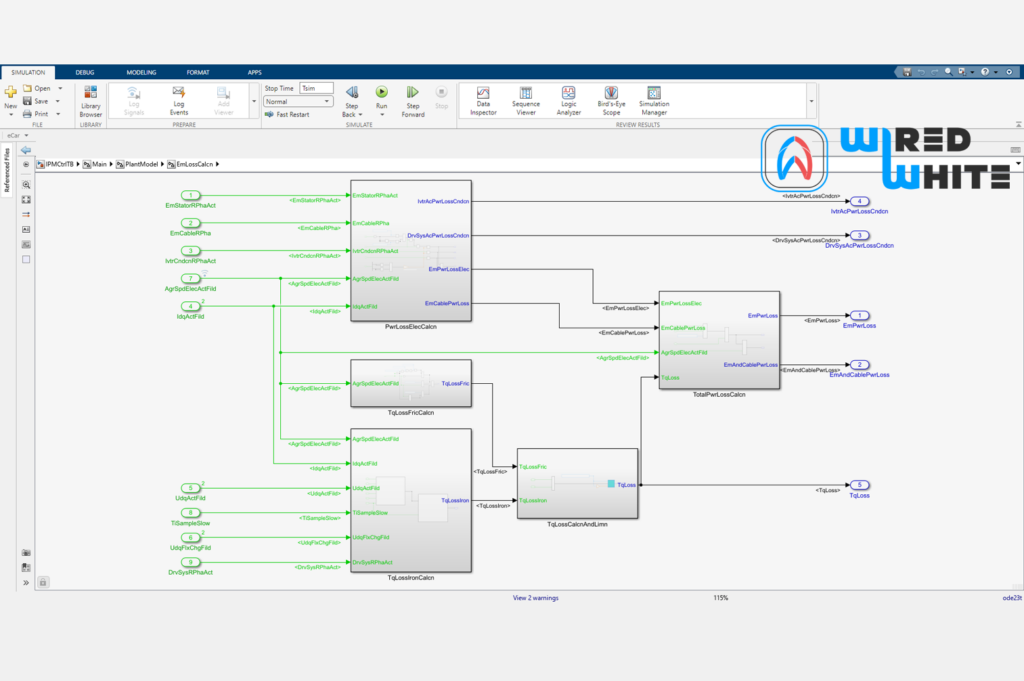

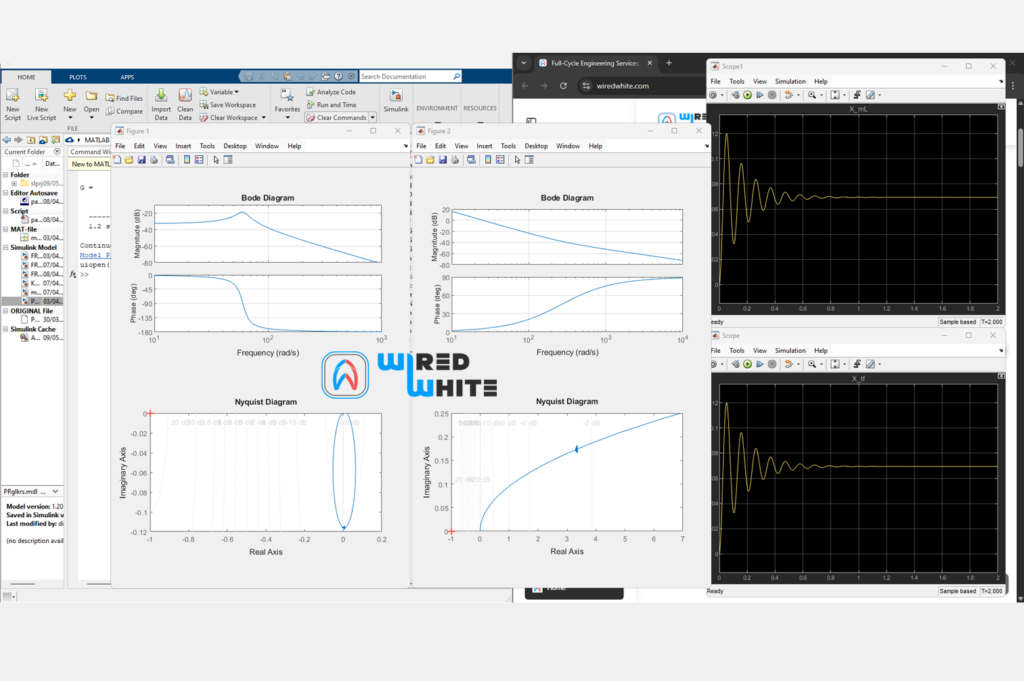

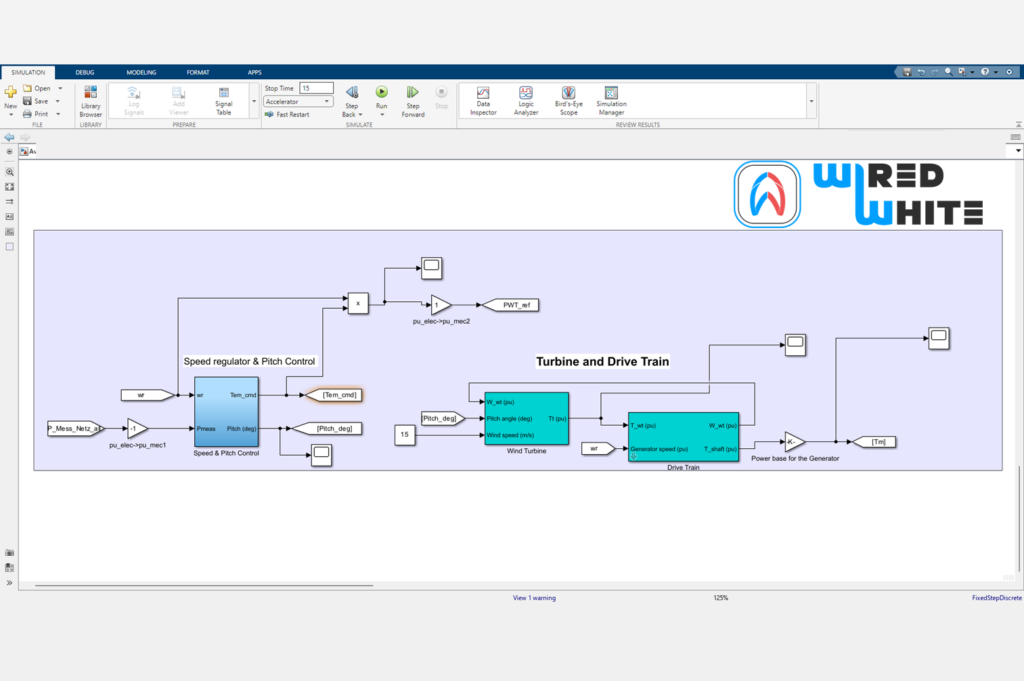

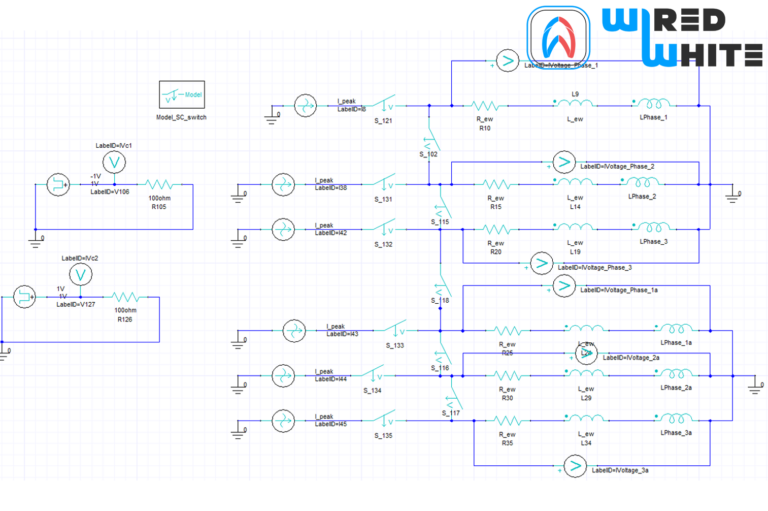

🧠 Simulation & Control

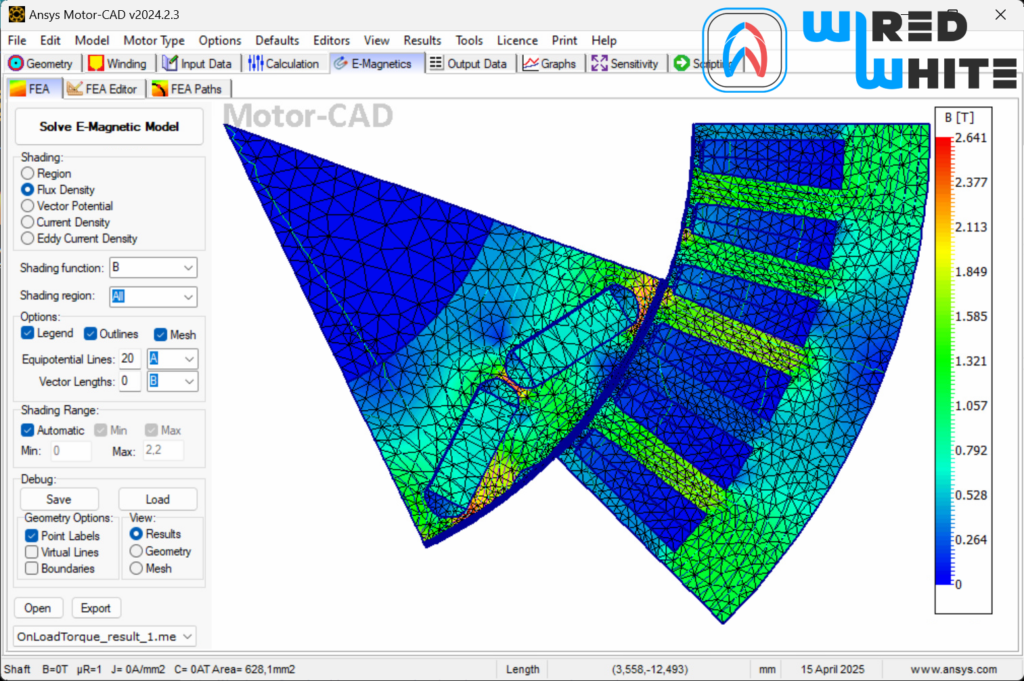

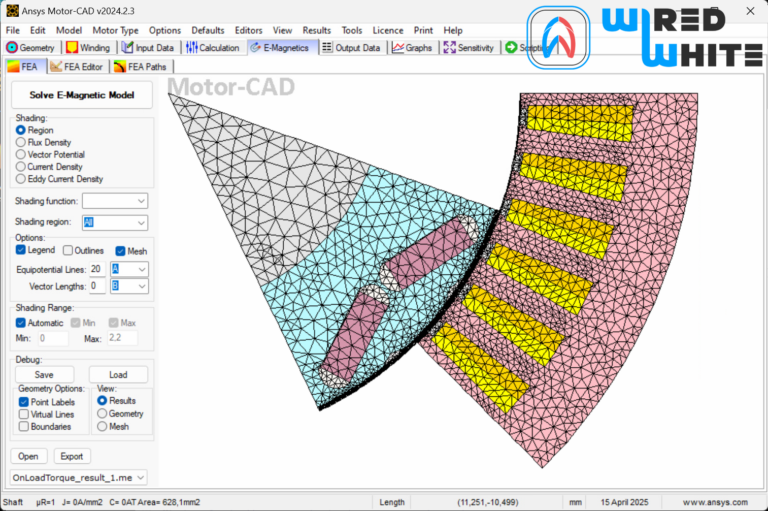

- FEM/FEA analysis

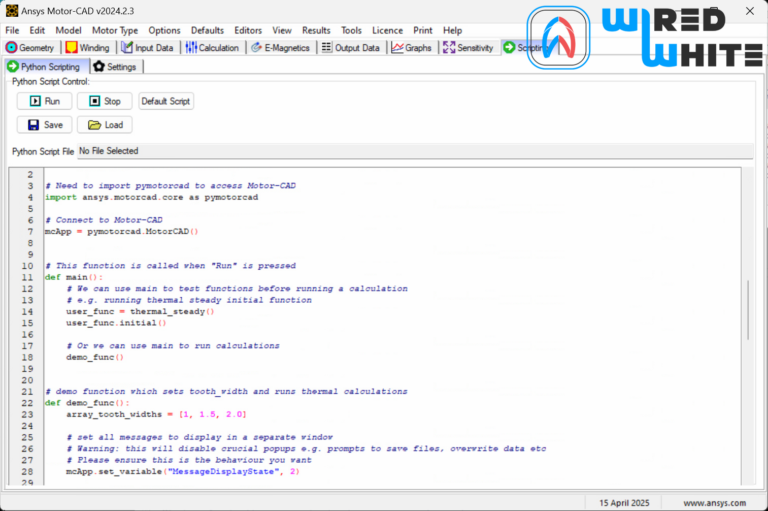

- Motor-CAD, Ansys Maxwell 2D & 3D

- Drivetrain & system simulation

- 1D simulations

- Motor control algorithm design (FOC, vector control)

- Model-based software development (MatLab, Simulink, Simscape, Plecs, TargetLink)

- Derating algorithms to protect eDrive and vehicle

- Development of functional safety (FuSA) compliant software functions

✅ Validation & Verification

- Test bench support: Sample A/B/C/D, prototype, and type testing

- Creation of Design Validation Plans

- Compliance for ISO26262, DO160, DO178c, IEC 60034-18

From Power Tools to Aerospace — Scalable, Standards-Aligned Solutions

- 🔌 Supported Voltage Levels:

- ⚡ Power Ranges:

- 🚗 Applications Covered:

- 12–48V: power tools, conventional automotive

- 48V: Hybrid electric automotive, marine applications

- 400V: Electric vehicles, rolling stock, machinery & construction

- 800V: eBus & eTruck, racing cars, mining, aviation

- 1200V–2400V: Aerospace, heavy-duty, power energy

- <100kW: Mild hybrids, starters, generators

- 100kW–300kW: EV, BEV, HEV, PHEV, EREV

- 150kW–600kW: Public transport, commercial vehicles and mining vehicles

- 650kW–1MW: Aviation, aerospace

- >1MW: Wind energy, power plant generators

- Alternator starter, starter generator, automotive alternator, range extender

- Central traction drive, axle drives, eAxle

- eVTOL & microliner propulsion

- Industrial machines, mining equipment

- Robotics

- Wind turbine generator, power plant generators

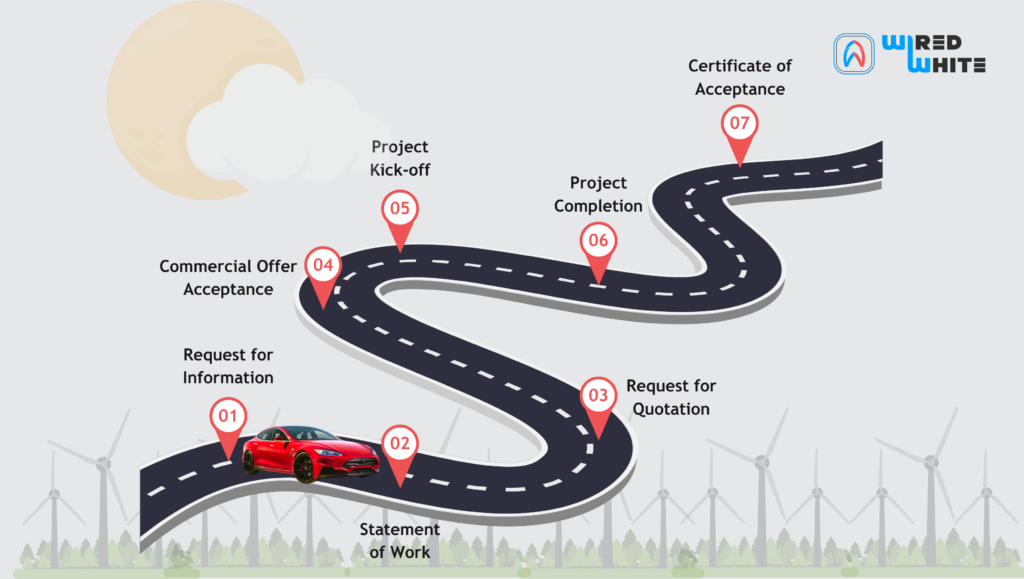

Proven Motor Development Processes and Engineering Excellence

Agile and Certified Development Processes that Deliver Engineering Practices:

- ASPICE

- V-Model

- Kaizen & Lean

- Six Sigma

- Agile, Scrum, Kanban Processes, Sprint Planning

Interdisciplinary Mechanical, System-Level and Project Management Support:

- CAD design, drawing creation of motor components

- System-level modeling & simulation

- Mechanical integration into overall system

- Stress analysis: CAD engineering, FEM calculations

- Project management, product owner, scrum master support

Advanced Engineering Tools and Collaboration Platform for Electric Motor Development

Our powerful tech stack enables fast, precise, and collaborative engineering workflows:

Specialized Simulation Software for Electric Motors

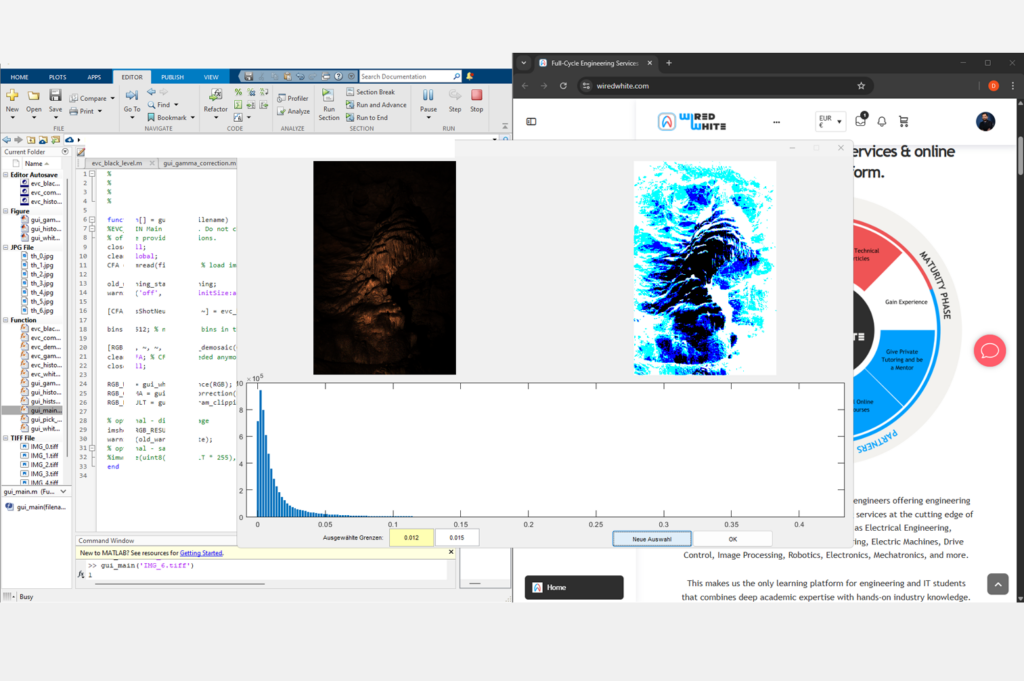

- Ansys Maxwell 2D – FEM-based electromagnetic simulations

- Motor-CAD – Thermal and electromagnetic analysis for e-motor systems

- MATLAB & Simulink – Model-based development, control algorithms, and system simulation

Integrated Collaboration Tools: WiredWhite Platform

- Project-specific workspaces for seamless teamwork

- Kanban boards and task management

- Video conferencing with screen sharing and recording

- Structured document handling and other useful tools

Supporting Standard Software

- Microsoft 365 – Teams, Word, Excel, PowerPoint for communication and documentation

Real-World Engineering Risks in Electric Motor Projects

Motors often run into trouble. Not because of one miscalculation — usually it’s the whole system acting up. Typical issues pop up like this:

Thermal limits

High-power designs often overheat before torque or efficiency targets are met. Cooling is tricky, insulation ages faster than expected, and derating kicks in sooner than simulations predict.

Magnet performance

Permanent magnets can weaken quickly under temperature spikes, short circuits, or aggressive field weakening. Skip proper checks, and performance drops almost immediately.

NVH surprises

Vibrations and noise show up late, when EM forces meet structural resonances and bearings. Fixing this after the prototype is expensive, but it happens in almost every high-speed motor.

Control software quirks

FOC loops can go unstable, sensors might be misaligned, and missing fault handling can break the drive — even if the hardware is fine.

Certification headaches

Safety standards like ISO, DO, or IEC often catch teams off guard. If you don’t plan for compliance early, retrofitting can mean big redesigns.

The takeaway

The key is early system-level modeling, realistic operating assumptions, and continuous checks across EM, thermal, mechanical, and control domains. Do these, and you avoid the usual traps.

Typical projects we support

- EV traction motors: PMSM (SPMSM, IPMSM), EESM, ASM, BLDC, SynRM.

- Industrial servo drives

- Robotics actuators and e-drives

- High-speed compressors and pumps

- Power Generators for Wind Energy

We handle:

- RFI, RFQ, supplier selection, vendor coordination, stakeholder management

- Requirement engineering

- Concept validation

- Motor design and optimization

- EM, Thermal, NVH, and control modelling and analysis

- V-Model, Validation and Verification

- Project management (Kanban, Waterfall, Gantt-Chart)

- Process management (Scrum, Lean Kaizen, Agile)

We support the process of:

- Mass manufacturing

- Certification bodies

Send us:

- Motor type and key requirements

- Target power & speed operating points or characteristics

- Current challenge or problem description

We’ll reply with:

- Initial Estimates

- Feasibility check

- Risk assessment

- Suggested workflow for your project

Accelerated Timelines. Certified Designs. Proven Outcomes.

⏱ 30%

faster prototype-to-validation cycle

⚙️ 100%

traceable and transparent working process

🧪 Complete

test support from sample A to type approval

✅ 100%

compliance rate on certified projects

Motor Solutions for Every Business

Sara, Account-ManagerinSOLCOM GmbH

Katharina, Team Lead Rolling Stockemagine GmbH

Martin, Domain Lead Electrical SystemsALSTOM Drives GmbH

Stefanie, Service Delivery Managerinemagine GmbH

Theresa, Proficient Key Account ManagerSOLCOM GmbH

Max, Technical Project Lead E-DrivesNidec Motors & Actuators (Germany) GmbH

Franziska, Principal ConsultantAmoria Bond GmbH

Seán, Chief Executive OfficerGrip Factory Munich GmbH

Let’s Build Your Next Motor

No matter the voltage, power, or application—our expert team delivers precision-engineered motors with test-proven performance.

- Free consultation call

- Contact form

Partner with Us for Your Next Motor Development Project

Speak directly with our engineers to discover how we can help you design, optimize, and certify electric motors — faster and with full compliance.

Let’s move your ideas forward.

Explore All Our Business Services

We offer full-cycle engineering services ranging from small consulting projects to extensive R&D projects, where we support throughout the entire product development process.