Ansys Deep Dive: In-depth Analysis from WiredWhite

In the realm of engineering and design, the pursuit of perfection often requires cutting-edge tools that can simulate, analyze, and optimize complex systems with unparalleled accuracy. Among these tools, Ansys stands out as a beacon of innovation, offering engineers and researchers a suite of powerful solutions to tackle the most challenging problems across a multitude of industries. In this deep dive into Ansys, we will explore its capabilities, applications, and the transformative impact it has had on the world of engineering.

Introduction to Ansys

Ansys, short for Analysis Systems, is a leading provider of engineering simulation software and services. Founded in 1970 by Dr. John Swanson, Ansys has since evolved into a global powerhouse, serving thousands of customers in industries ranging from aerospace and automotive to healthcare and electronics.

At its core, Ansys enables engineers to simulate the behavior of physical systems under various conditions, allowing for virtual testing and optimization before a single prototype is built. This approach not only accelerates product development but also minimizes costs and reduces the need for physical testing, ultimately leading to more innovative and efficient designs.

The Anatomy of Ansys

Ansys offers a diverse portfolio of simulation tools tailored to different engineering disciplines and applications. Here are some key components of the Ansys ecosystem:

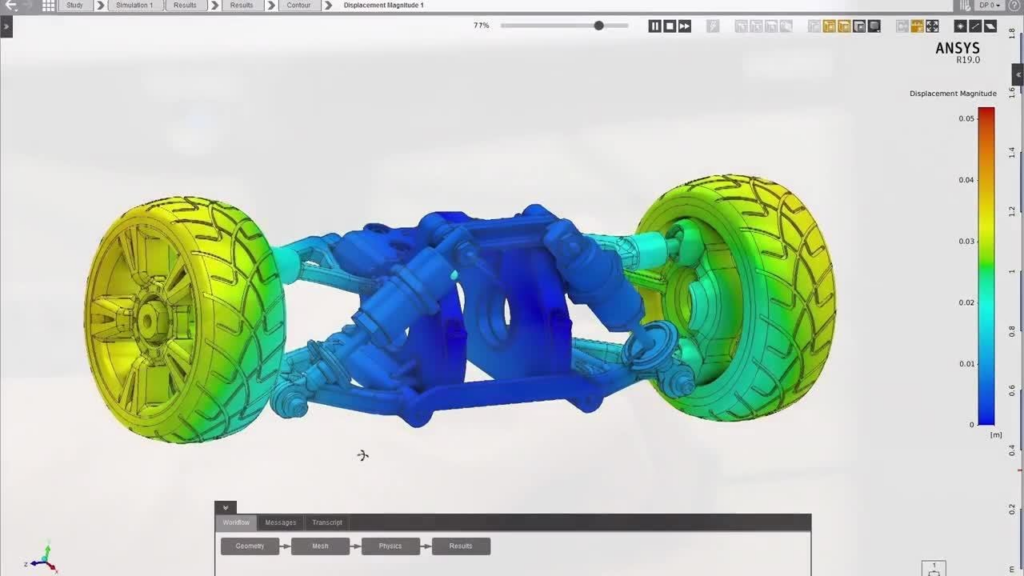

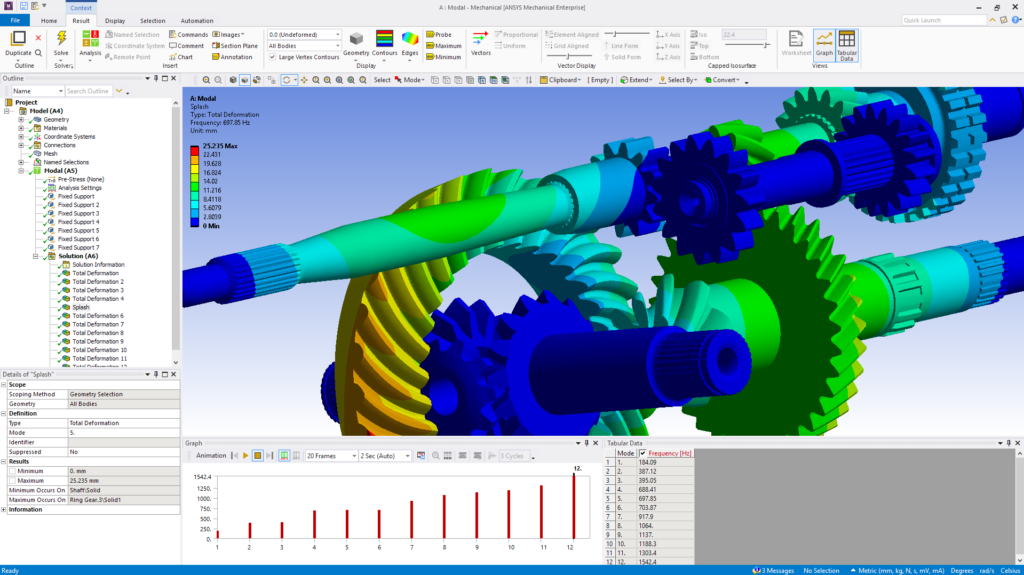

Finite Element Analysis (FEA): Ansys Mechanical allows engineers to analyze the structural integrity and performance of mechanical components and systems through finite element analysis. This includes assessing factors such as stress, deformation, and vibration.

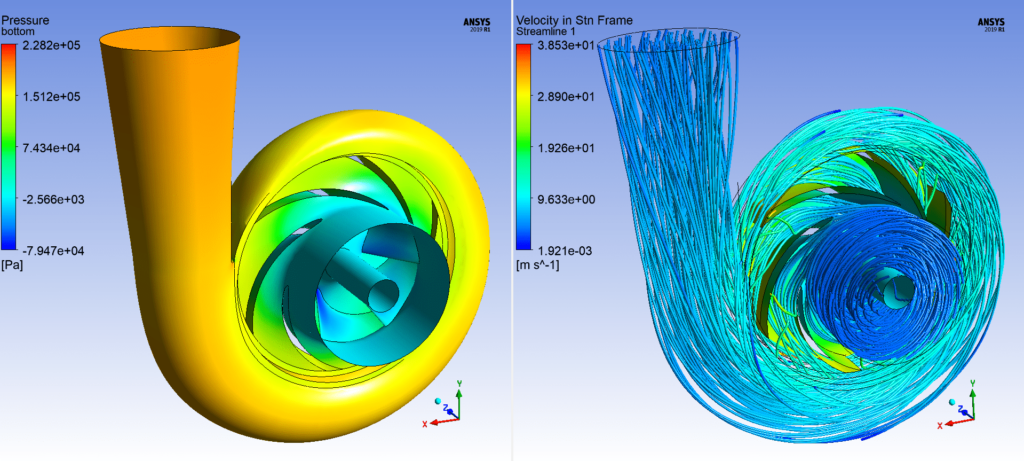

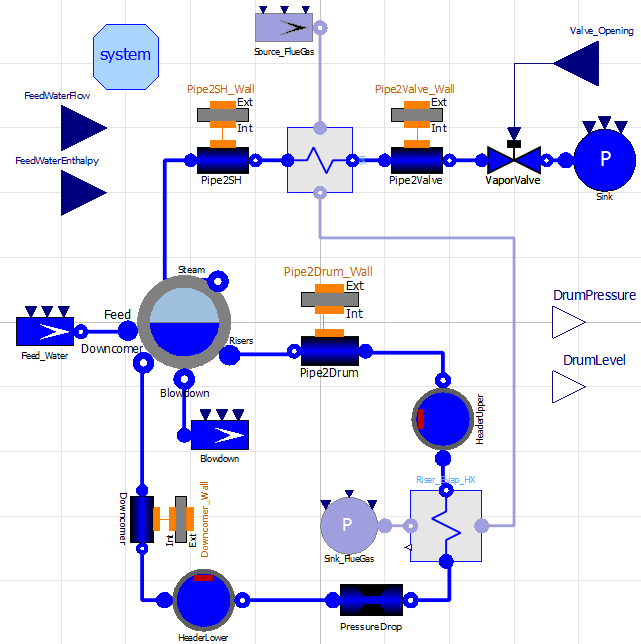

Computational Fluid Dynamics (CFD): With Ansys Fluent and Ansys CFX, engineers can simulate fluid flow and heat transfer phenomena in a wide range of applications, from aerodynamics and combustion to chemical processing and HVAC systems.

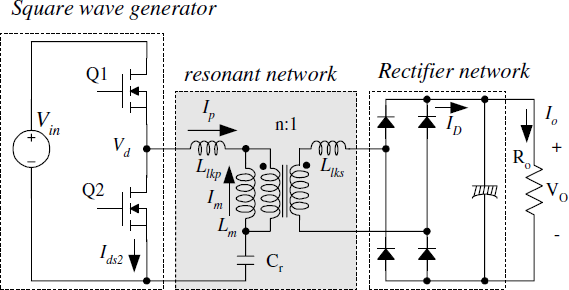

Electromagnetics (EM): Ansys Maxwell and Ansys HFSS enable the simulation of electromagnetic fields and effects, essential for designing antennas, motors, sensors, and electronic devices.

Multiphysics Simulation: Ansys Multiphysics brings together various physics disciplines, allowing engineers to analyze coupled phenomena such as fluid-structure interaction, thermal-electrical coupling, and acoustic-vibration coupling.

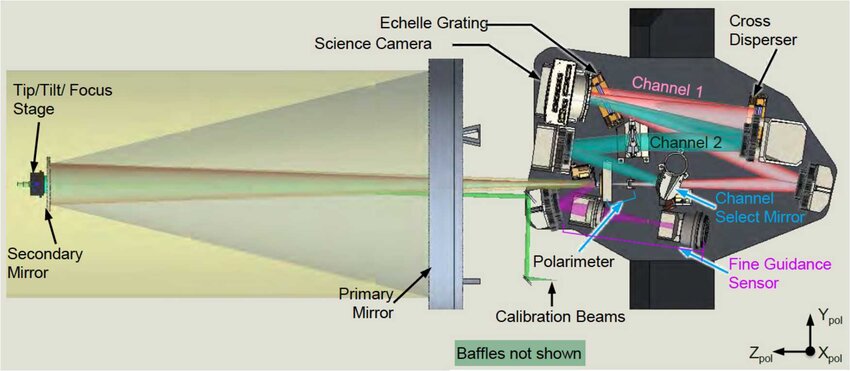

Optical Simulation: Ansys SPEOS simulates light propagation and optical systems, facilitating the design of lighting, displays, cameras, and other optical devices with precision and realism.

System Simulation: Ansys Simplorer offers a platform for simulating and optimizing complex systems and control systems, helping engineers understand the behavior of interconnected components and subsystems.

Applications Across Industries

The versatility of Ansys extends across a wide range of industries, where its simulation capabilities play a crucial role in innovation and problem-solving:

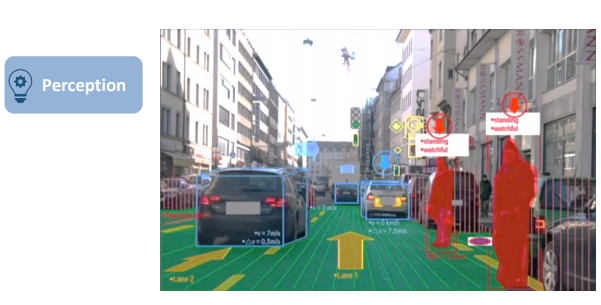

Automotive: Ansys is used for virtual prototyping and optimization of vehicle components and systems, including structural integrity, crashworthiness, aerodynamics, and thermal management.

Aerospace: From aircraft design and analysis to space exploration and satellite communications, Ansys plays a pivotal role in ensuring the safety, reliability, and performance of aerospace systems.

Electronics: Ansys aids in the design of electronic devices, circuit boards, and semiconductor components, addressing challenges related to signal integrity, power integrity, electromagnetic compatibility, and thermal management.

Energy: In the energy sector, Ansys helps optimize the design and operation of power plants, renewable energy systems, and energy storage technologies, contributing to efficiency improvements and sustainability goals.

Biomedical: Ansys is utilized for simulating medical devices, implants, and biological systems, facilitating advancements in areas such as prosthetics, cardiovascular devices, drug delivery systems, and patient-specific treatment planning.

Consumer Products: Ansys enables the design and optimization of consumer products ranging from smartphones and household appliances to sports equipment and wearable devices, enhancing performance, durability, and user experience.

Advancements and Innovations

Over the years, Ansys has continually pushed the boundaries of engineering simulation through technological advancements and strategic acquisitions. Some notable developments include:

High-Performance Computing (HPC): Ansys leverages parallel computing and cloud computing to significantly accelerate simulation times, enabling engineers to tackle larger and more complex problems with ease.

Machine Learning and AI: Ansys incorporates machine learning algorithms into its software to automate simulation workflows, optimize designs, and extract insights from vast amounts of simulation data.

Digital Twin Technology: Ansys facilitates the creation of digital twins—virtual replicas of physical assets or systems—enabling predictive maintenance, performance optimization, and real-time monitoring across various industries. For a deep dive into Digital Twins, read our blog https://wiredwhite.com/harnessing-the-power-of-digital-twins-revolutionizing-industries/

Materials Simulation: Ansys Granta provides comprehensive materials data and simulation tools, empowering engineers to make informed decisions about material selection, performance, and sustainability.

Future Prospects and Challenges

Looking ahead, Ansys is poised to play an even more significant role in shaping the future of engineering and innovation. However, several challenges and opportunities lie on the horizon:

Complexity Management: As engineering systems become increasingly complex, there is a growing need for intuitive and integrated simulation platforms that can handle multidisciplinary challenges seamlessly.

Interoperability and Collaboration: Enhancing interoperability between different simulation tools and fostering collaboration across teams and organizations will be crucial for maximizing the impact of simulation-driven design.

Sustainability and Resilience: Ansys can contribute to sustainability efforts by enabling the design of more energy-efficient products, reducing waste through virtual prototyping, and optimizing resource utilization across the product lifecycle.

Ethical Considerations: As simulation technology becomes more powerful, it raises ethical questions about its use, particularly in fields such as autonomous vehicles, healthcare, and defense.

Conclusion on Ansys Deep Dive

In conclusion, Ansys stands as a cornerstone of engineering simulation, empowering engineers and researchers to tackle complex challenges with confidence and creativity. Its diverse portfolio of tools, coupled with ongoing advancements in technology, promises to drive innovation across industries and shape the future of design and engineering. As we continue to push the boundaries of what is possible, Ansys will undoubtedly remain at the forefront of simulation-driven innovation, unlocking new possibilities and transforming the way we envision and create the world around us. We highly recommend students but also professionals to upgrade their skills by learning how to use Ansys and its most commonly used tools.

Responses