How to Ace the Fusion 360 Certified User Examination

Fusion 360 is Autodesk’s flagship CAD/CAM software, widely used in product design, mechanical engineering, and manufacturing. Achieving the Fusion 360 Certified User credential validates your skills and opens doors in design and manufacturing careers. This guide provides a clear roadmap, step-by-step strategies, sample questions, visuals, and resources to help you succeed.

1. Understand the Exam Structure

The Fusion 360 Certified User Exam tests your understanding of:

Sketching & Modeling: 2D sketches, constraints, dimensions, extrusions, revolves.

Assembly: Creating components, joints, and motion studies.

Simulation & Analysis: Basic static stress analysis, understanding forces.

Manufacturing Basics: CAM setup, toolpaths, and CNC operations.

Documentation: Creating drawings, annotations, and technical details.

| Topic | Approx % of Exam |

|---|---|

| Sketching & Modeling | 35% |

| Assembly | 25% |

| Simulation | 15% |

| Manufacturing | 15% |

| Documentation | 10% |

Official Resources:

Fusion 360 Certified User Exam Guide (PDF) – exam objectives, question types, recommended skills.

Autodesk CAD Mechanical Design Associate Certification Prep – hands-on exercises covering all exam objectives.

2. Prepare Your Study Plan

Step 1: Know the Exam Objectives

Download the official Autodesk Fusion 360 Certified User guide and focus on each topic.

Step 2: Practice Hands-On

Fusion 360 is best learned by doing. Daily 1–2 hours should include:

Creating sketches with constraints and dimensions

Modeling parts with extrude, revolve, loft, and fillet

Assembling components with joints and motion studies

Running simulation tests

Preparing drawing sheets with dimensions and notes

Step 3: Use Training Resources

3. Master Key Fusion 360 Features

a) Sketching & Constraints

Focus on parametric design

Learn dimension types: linear, angular, diameter

Practice project/include geometry

Visual: Sketch of rectangle with a centered circle, labeled dimensions and constraints.

b) 3D Modeling

Understand feature order and timeline

Practice extrude, revolve, loft, sweep, fillet, chamfer

Master patterns and mirroring

Visual: Bracket model showing extrusion and fillets

c) Assembly

Learn rigid, revolute, slider, ball joints

Practice motion studies and exploded views

Visual: Two parts assembled with a revolute joint

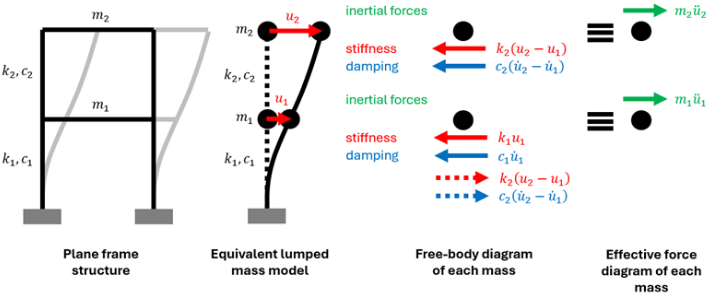

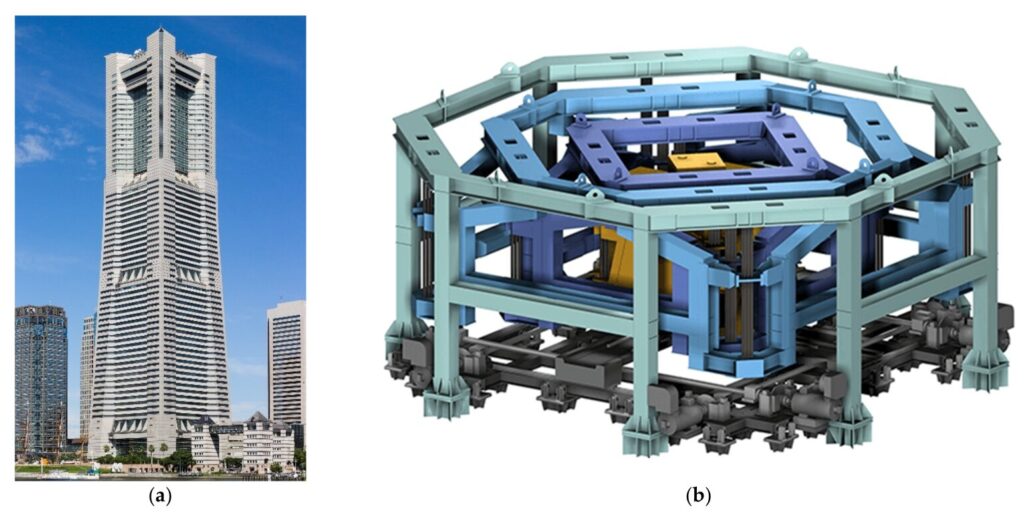

d) Simulation Basics

Apply static loads and constraints

Check stress, displacement, and safety factors

Visual: Part under static stress with color-coded stress distribution

e) Manufacturing

Set up CAM operations: 2.5D milling, drilling

Define tools, toolpaths, stock setup

Simulate machining processes

Visual: CAM setup with toolpaths on a part

Practice Resources:

4. Take Practice Exams

Attempt 3–5 practice tests

Time yourself; exams are 60–90 minutes

Review mistakes carefully

Sample Question

Question:

You are creating a bracket in Fusion 360. The bracket has a 50mm diameter hole at the center. The distance from the bottom edge to the hole center is 30mm. Which steps correctly apply dimensions and constraints?Options:

A) Draw the circle, apply diameter, then apply vertical dimension from bottom edge to center.

B) Draw the circle, apply horizontal dimension, then use coincident constraint.

C) Draw the circle without constraints.

D) Draw the circle and extrude immediately.Answer: A – Properly constraining the sketch ensures parametric control and prevents errors during modifications.

Visual: 2D sketch with rectangle and centered circle showing applied dimensions.

5. Exam Day Strategy

Read all questions carefully – scenario-based exam

Plan your time – don’t get stuck on one question

Use shortcuts & workflow knowledge – modeling efficiency matters

Save and review work – double-check dimensions, joints, simulation setups

6. Post-Exam Tips

Showcase certificate on LinkedIn or portfolio

Review weak areas if exam is failed, and re-attempt

Continue practical projects for deeper skill

Additional Resources:

Quick Reference Checklist

Understand exam objectives

Practice sketches & constraints daily

Model 3D parts with parametric features

Assemble components and study joints

Perform basic simulation analysis

Set up CAM toolpaths for manufacturing

Take multiple practice exams

Revise mistakes and weak points

Mastering Fusion 360 requires consistent hands-on practice. By following this guide and leveraging the linked resources, you can confidently achieve your Fusion 360 Certified User credential.

Keywords: Fusion 360

Responses