Facts about Finite Element Method (FEM)

Finite Element Method (FEM) or Finite Element Analysis (FEA) is a numerical method used for solving complex engineering problems. It is a powerful tool that enables engineers to analyze structures and systems to determine their performance under various conditions.

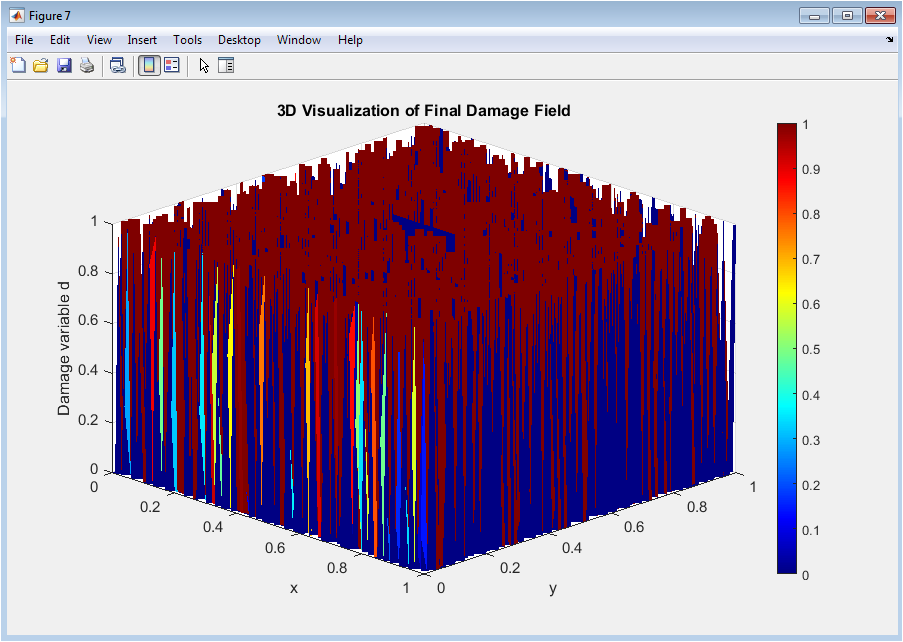

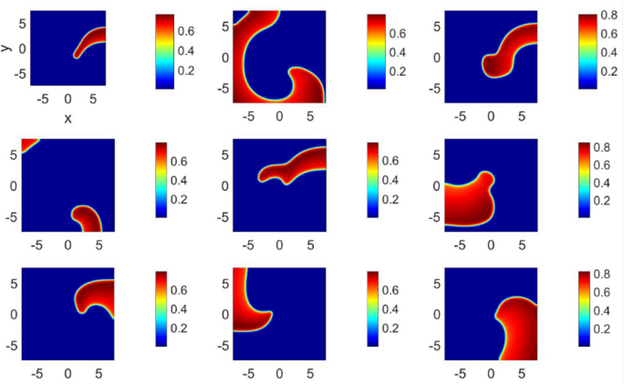

The Finite Element Method/Analysis solves partial differential equations that arise in engineering and physics. It involves dividing the problem domain into smaller, simpler regions called finite elements. These elements are then connected to form a mesh or a grid. The governing equations are solved for each element. Afterwards, the solutions are combined to obtain the overall solution for the system.

FEM/FEA is used in various fields of engineering, such as:

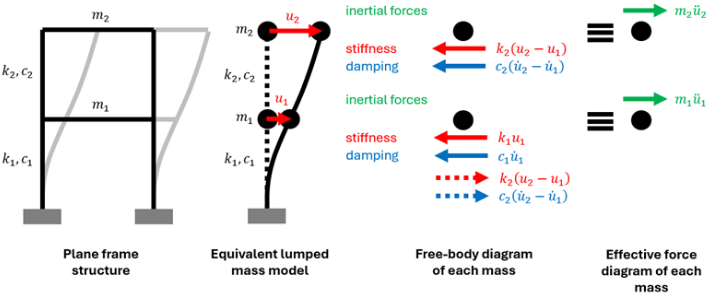

- Structural Analysis: FEM/FEA is used to analyze the behavior of structures under different loading conditions. It is used to determine the stress and strain distribution in a structure, the deformation of the structure, and the natural frequencies of the structure.

- Fluid Dynamics: FEM/FEA is used to solve fluid flow problems, such as calculating the pressure and velocity distribution in pipes, channels, and other flow systems.

- Heat Transfer: FEM/FEA is used to analyze the heat transfer in various systems, such as heat exchangers, boilers, and furnaces.

- Electromagnetics: FEM/FEA is used to analyze electromagnetic fields, such as those found in motors, transformers, and other electrical equipment.

FEM/FEA has become an essential tool in modern engineering design and analysis because it enables engineers to simulate complex physical systems and predict their behavior under various conditions. Need help with FEM / FEA Projects? Seek support from our exceptional engineers:

Responses