Advanced Modeling & Simulation of Electric Drivetrains

Modelling and simulation of electric drivetrains, electrical drives, permanent magnet synchronous machines, inverters, power converters and propulsion systems.

Solve Your Electric Drivetrain Modeling and Simulation Challenges:

Struggling with unclear requirements, time-consuming feasibility reviews, or supplier bottlenecks?

❌ Lack of Accurate System-Level Modeling

❌ Difficulty in Matching and Parametrizing Powertrain Components

❌ Insufficient Derating Strategies Leading to Drive Failures

❌ Inaccurate Performance and Efficiency Calculations

❌ Thermal Issues Due to Inadequate Heat Management Models

❌ High Cost and Risk Due to Incomplete Test & Validation

Accelerate your roadmap and avoid costly rework with proven engineering practices.

Comprehensive Electric Drivetrain Modeling and Simulation

🔧 Design & Feasibility

- Requirement engineering

- System modelling & design

- Software/component level requirement breakdown

- Feasibility study & review of third-party designs

- Supplier sourcing, prototype purchasing

- RFI, RFQ process organization and review

- Prototype manufacturing

- Unit tests, SW integration & validation tests

- Matching Power Converter to the electric machine

- Model parametrization

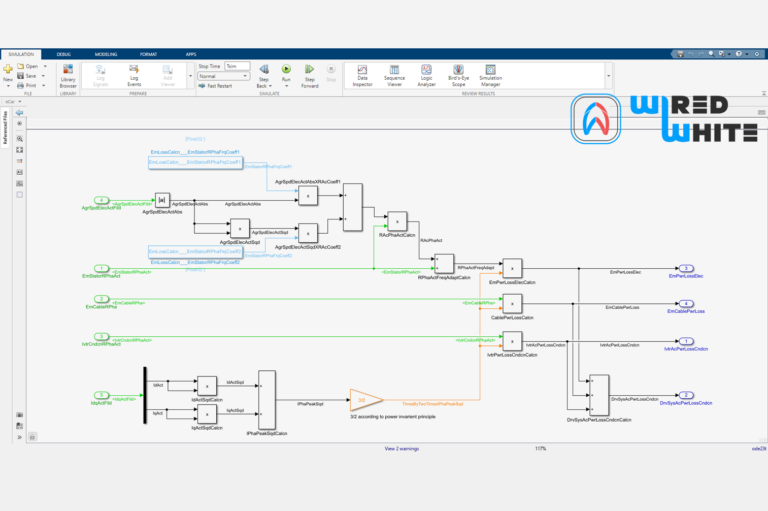

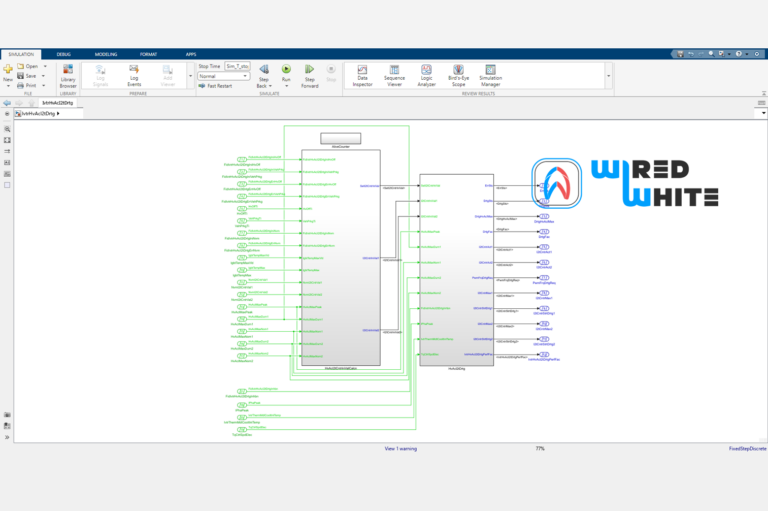

- Modelling & simulation of: synchronous machines (internal & surface mounted PMSM), Direct current (DC) motors, Asynchronous motors (ASM), Reluctance motors (SynRM), etc.

- System & drivetrain simulations

- Model-based software development

- Functional safety (FuSA)-compliant software

- Software project management

⚡ Advanced Motor Control Solutions

- Motor control algorithms: FOC / Vector control

- Torque, Speed & Power Control

- Sensorless Control Techniques

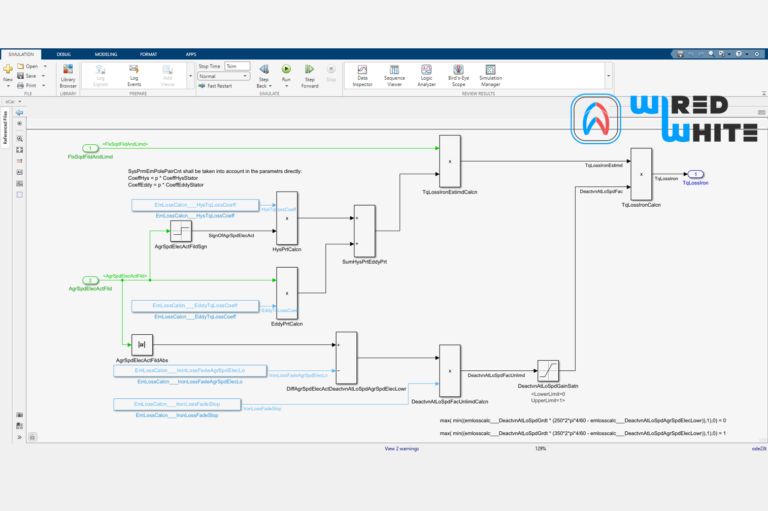

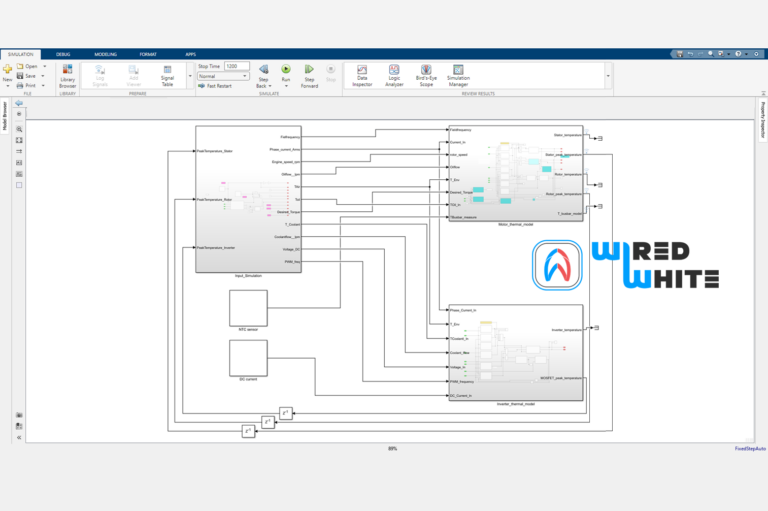

♨️ Thermal Modeling

- Thermal model creation & parametrization

- S1/S3, Rated & Peak curves

- In-depth thermal simulations & analysis

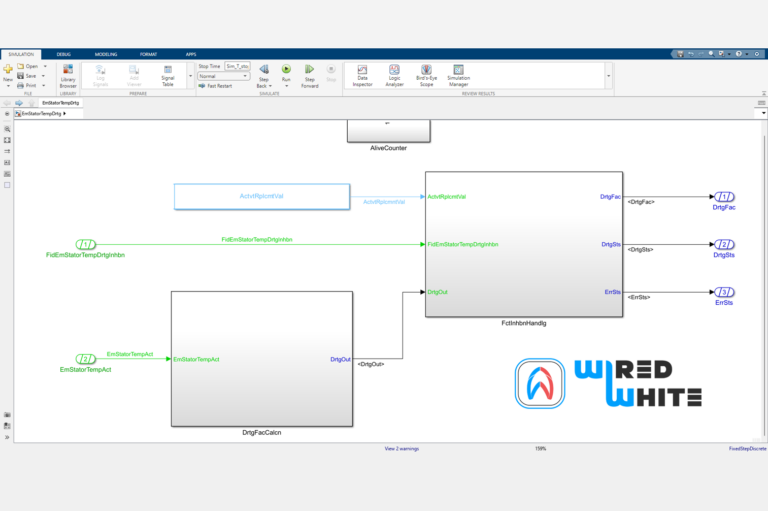

🧠 Intelligent Derating Functions

- Rotor & Stator Temperature Derating

- Inverter Coolant Temperature Derating

- HV AC/DC Current (I²t) Derating

- IGBT Temperature Delta Derating

- Inverter PWM Frequency & NTC Temp Derating

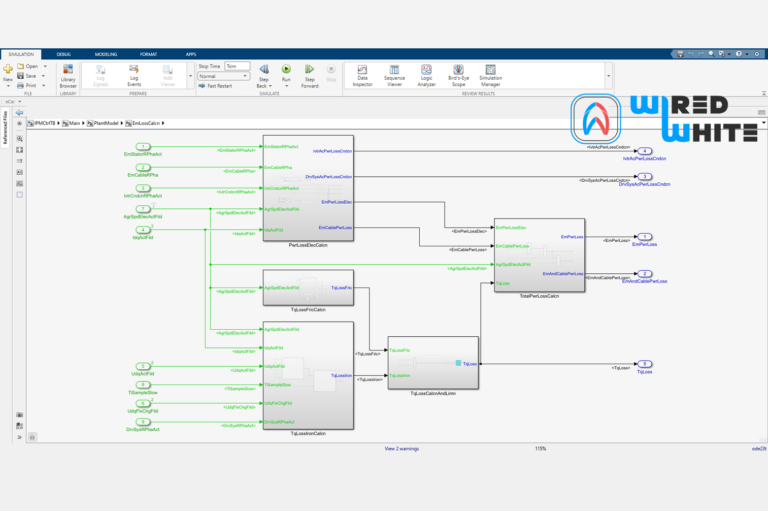

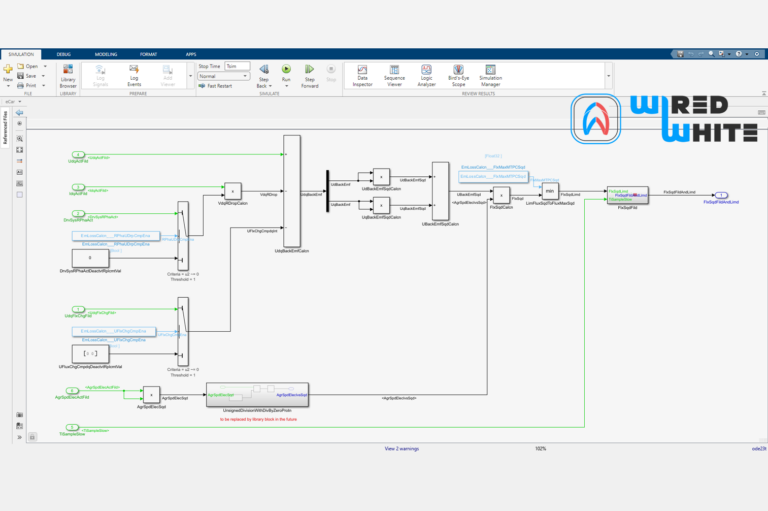

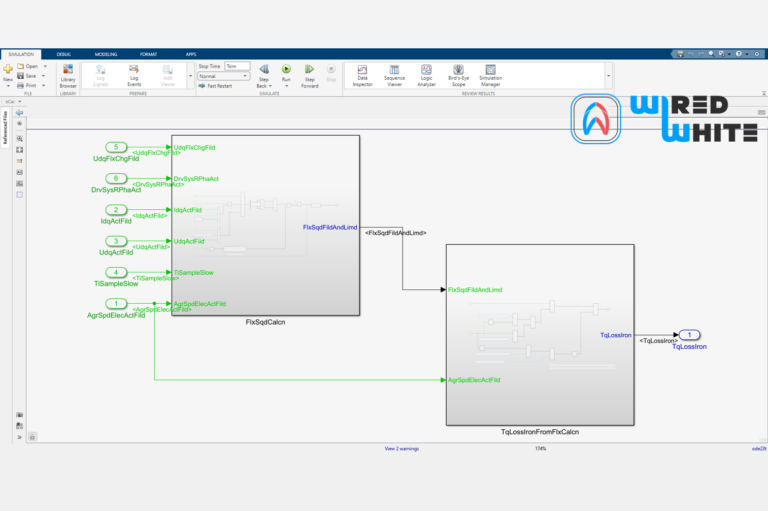

📉 Detailed Loss Modeling for Peak Drivetrain Efficiency

- Electric motor loss determination

- Friction, proximity, skin effect, iron & magnet loss analysis

- Thermal efficiency maps under varied conditions

- Software parametrization, curve fitting & optimization

✅ Validation & Verification

- Rigorous Testing & Validation According to Global Standards

- Test bench support: Sample A/B/C/D, prototype, and type testing

- Creation of Design Validation Plans

- Compliance for ISO26262, DO160, DO178c, IEC 60034-18

Powering Every Industry: Scalable Voltage, Versatile Applications

- 🔌 DC Voltage Levels:

- ⚡ Power Ranges:

- 🚗 Applications Covered:

- 12–48V: conventional systems

- 48V: hybrid & low power

- 400V: traction drives, industrial machinery

- 800V: eBus, eTruck, mining

- 1200V–2400V: aerospace

- 5–25kW: starter/generator/mild hybrid

- 100–300kW: electric/hybrid vehicles

- 150–600kW: eBus, eTruck, mining

- 650–1000kW: racing, aerospace

- 10MW: wind power, energy applications

- BEV, EREV, PHEV, HEV

- Electric Busses & Trucks (traction, axial drive)

- Heavy-duty trucks & machinery

- eVTOL, hybrid electric aviation

- Mining & industrial applications

Proven Electric Drivetrain Modeling and Simulation Excellence

Drivetrain Development That Meets Industry Standards:

- ISO26262

- DO160

- DO178c

- IEC 60034-18

Agile & Certified Engineering Processes That Drive Results:

- ASPICE

- V-Model

- Kaizen & Lean

- Six Sigma

- Agile, Scrum, Kanban Processes, Sprint Planning

Interdisciplinary Mechanical, System-Level and Project Management Support:

- CAD design, drawing creation of motor components

- System-level modeling & simulation

- Mechanical integration into overall system

- Stress analysis: CAD engineering, FEM calculations

- Project management, product owner, scrum master support

Advanced Engineering Tools and Collaboration Platform for Electric Drivetrain Modeling & Simulation

Our powerful tech stack enables fast, precise, and collaborative engineering workflows:

Specialized Simulation Software for Electric Motors

- Ansys Maxwell 2D – FEM-based electromagnetic simulations

- Motor-CAD – Thermal and electromagnetic analysis for e-motor systems

- MATLAB & Simulink – Model-based development, control algorithms, and system simulation

- CANape, INCA, TargetLink, dSPACE, LabVIEW – ECU calibration, testing, code generation, and real-time validation

Integrated Collaboration Tools: WiredWhite Platform

- Project-specific workspaces for seamless teamwork

- Kanban boards and task management

- Video conferencing with screen sharing and recording

- Structured document handling and other useful tools

Supporting Standard Software

- Microsoft 365 – Teams, Word, Excel, PowerPoint for communication and documentation

Why WiredWhite is the Perfect Engineering Partner for You

⏱ 15+ Years

industry experience

👨 800+

networked engineering professionals

🔄 Integrated

project collaboration tools

✅ 100%

Proficient in advanced engineering tools

We Are Supporting Businesses, Executives, and Innovators Worldwide

Freelance Agencies

Teams of Engineers

Start-ups

Companies

Motor Solutions for Every Business

Sara, Account-ManagerinSOLCOM GmbH

Katharina, Team Lead Rolling Stockemagine GmbH

Martin, Domain Lead Electrical SystemsALSTOM Drives GmbH

Stefanie, Service Delivery Managerinemagine GmbH

Theresa, Proficient Key Account ManagerSOLCOM GmbH

Max, Technical Project Lead E-DrivesNidec Motors & Actuators (Germany) GmbH

Franziska, Principal ConsultantAmoria Bond GmbH

Seán, Chief Executive OfficerGrip Factory Munich GmbH

- Free consultation call

- Contact form

Partner with Us for Your Electric Drivetrain Modeling & Simulation Project

Speak directly with our drivetrain experts to explore how we can help you model, simulate, and validate electric propulsion systems — with speed, precision, and full standards compliance.

Let’s move your ideas forward.