Smart Warehouse using CISCO Packet Tracer and IOT devices

Abstract –

This project presents the design and implementation of a Smart Warehouse using CISCO Packet Tracer and IoT devices. The system leverages IoT technology to automate safety, security, and environmental control within the warehouse. Key features include fire detection and automated extinguishing systems, motion sensors, webcams, and smart doors for enhanced security. Worker safety is prioritized through real-time fire alerts and environmental monitoring. Smart appliances like fans, lights, and ACs improve worker comfort and operational efficiency. A thermostat maintains optimal storage conditions for sensitive goods. All devices are integrated through a central gateway and controlled remotely via smartphone. The system reduces human intervention and operational costs. This unified, automated approach surpasses traditional semi-automated warehouse systems. The model enhances safety, productivity, and quality assurance in warehouse environments. The Internet of things (IOT) is the extension of Internet connectivity into physical devices and everyday objects. Embedded with electronics, Internet connectivity, and other forms of hardware; these devices can communicate and interact with others over the Internet, and they can be remotely monitored and controlled. In the mining industry, IOT is used as a means of achieving cost and productivity optimization, improving safety measures and developing their artificial intelligence needs.

Objective –

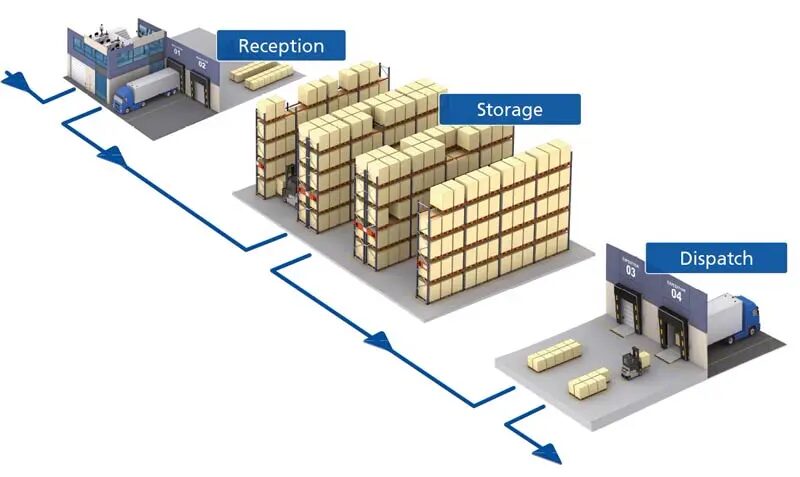

The objective of this project is to develop a fully automated Smart Warehouse system using CISCO Packet Tracer and IoT devices that enhances worker safety, product security, and storage quality. By integrating multiple smart sensors and appliances through a centralized gateway, the system aims to provide real-time monitoring, control, and automation of various warehouse functions, minimizing human intervention and operational costs while maximizing efficiency, safety, and product quality. Warehouse is the place in which is used by manufactures, importers, exporters, customs, transport business etc. to store their products. With the help of Smart Warehouse we can not only improve the safety of the the workers working inside the warehouse but also we can improve the security and quality of the product stored inside the warehouse.

You can download the Project files here: Download files now. (You must be logged in).

Introduction:

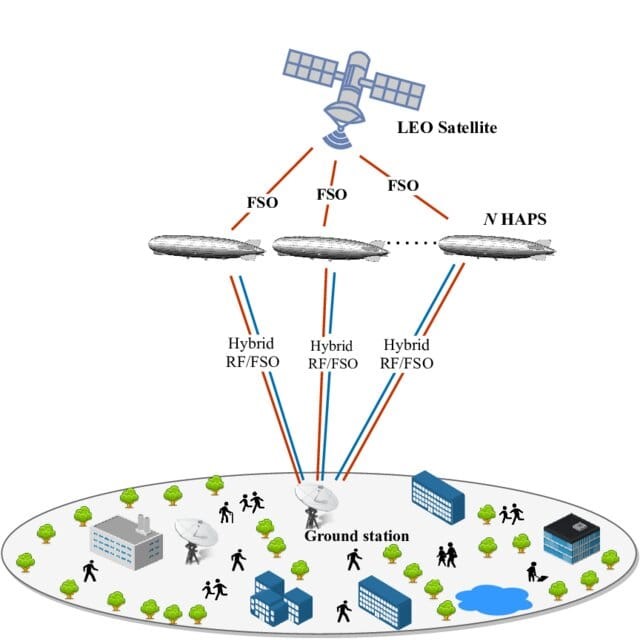

Warehousing plays a vital role in supply chain management and logistics, serving as a critical node for storing goods before distribution. However, traditional warehouse systems often face challenges such as poor safety measures, inefficient energy management, and lack of centralized control. With the rise of digital transformation, integrating the Internet of Things (IoT) into warehouse operations offers a revolutionary approach to overcoming these limitations. IoT enables real-time monitoring, automation, and intelligent decision-making by interconnecting physical devices such as sensors, actuators, and controllers with internet-based services [1] [3].

The Smart Warehouse system proposed in this project leverages CISCO Packet Tracer as a simulation platform to visualize and test the IoT-based architecture. The system includes components such as fire sensors, motion sensors, webcams, smart doors, and thermostats, which work together to ensure the safety of workers, secure access control, and maintain ideal environmental conditions for stored products. Smart appliances like lights, fans, windows, and air conditioners further enhance energy efficiency and user comfort. These components are managed through a microcontroller unit and connected via a centralized gateway that facilitates remote access and real-time control through a smartphone interface.

Unlike existing warehouse systems that operate with partial automation and require significant manual oversight, the proposed Smart Warehouse system is designed to be fully automated. It provides an integrated solution for fire detection and suppression, intrusion monitoring, environmental control, and energy-efficient operations. This comprehensive approach not only enhances worker safety and security but also ensures that sensitive products are preserved under optimal conditions. By implementing this model in CISCO Packet Tracer, the project demonstrates a scalable, efficient, and intelligent warehouse solution suitable for modern industrial and commercial applications.

Synopsis –

This project focuses on the development and simulation of a Smart Warehouse system using CISCO Packet Tracer and Internet of Things (IoT) technologies. The primary goal is to create an intelligent, fully automated warehouse environment that ensures worker safety, product security, and environmental control. The system integrates various IoT devices such as fire sensors, motion sensors, webcams, smart doors, thermostats, and smart appliances (e.g., lights, fans, air conditioners) into a centralized architecture. Each component communicates via a gateway, with control provided through a smartphone application or dashboard [1].

The Smart Warehouse system is designed to detect hazards such as fire and unauthorized access, respond in real-time using actuators like sprinklers or smart locks, and monitor conditions to ensure the quality of stored goods. The temperature and humidity levels are continuously regulated to match the storage requirements of various products. The entire system is virtually implemented and tested using CISCO Packet Tracer, offering a cost-effective simulation environment before physical deployment.

By minimizing manual interventions and leveraging real-time automation, this smart solution reduces labor costs, increases safety, and enhances the operational efficiency of traditional warehouse systems. It provides a blueprint for next-generation smart infrastructure applicable across industries like manufacturing, logistics, and retail [5].

The ability of the IOT devices and technology we can make the entire environment fully automatic which help in improving the safety of worker, security and quality of the product at the same time.

Worker safety has been one of the biggest issues in every environment or in any industry. So with the help of the IOT devices such as Fire sensor for monitoring the fire help in making them fell safe.

IOT can play a significant role to ensure worker safety in extreme environments as discussed above but appliances like smart lights. Smart ac, smart fan can help in improving the quality of life of the people. While devices like motion sensor, webcam and smart doors can help in increasing the security measures and smart ac with thermostat can help in maintaining the quality of product stored.

Literature Survey –

The evolution of smart technologies has significantly influenced industrial automation, particularly in the domain of warehousing and logistics. Numerous studies and implementations have highlighted the potential of IoT-based warehouse management systems in transforming conventional storage facilities into intelligent, real-time responsive environments. Traditional systems often rely heavily on manual operations or semi-automated setups, which can be inefficient, prone to human error, and limited in terms of adaptability and responsiveness.

Existing System – Most of the system proposed right now is mainly working separately and not fully automatic which increase the requirement of the money and labour for the same

Earlier works, such as those by Zhang et al. (2017), have explored sensor networks in warehouse environments for temperature and humidity monitoring. However, these implementations typically focus on a single functionality, such as product preservation, without integrating safety and security aspects. Other studies have demonstrated the use of fire sensors and motion detectors in isolated systems but lack centralized control or smartphone-based monitoring, which limits usability and responsiveness. Furthermore, many implementations do not offer full automation, requiring human intervention for actions like opening doors or activating cooling systems.

Introduced System – Introduced system not only focusing on making the safety of the worker and quality and security of the product with making everything fully automatic into consideration.

In contrast, the proposed system addresses these limitations by unifying multiple IoT devices under a centralized and fully automated framework. It builds on the gaps identified in previous systems—particularly the lack of integration, scalability, and real-time control. By using CISCO Packet Tracer for simulation, the project also introduces a cost-effective and accessible method for modeling and testing smart environments before physical implementation [3] [2]. The result is a comprehensive solution that enhances worker safety, strengthens security, and ensures product quality—all managed through intelligent automation.

You can download the Project files here: Download files now. (You must be logged in).

Component Used –

Hardware –

- Micro-controller Chip

- Fire Sensor

- Motion Sensor

- Webcam

- Thermostat

- Gateway

Appliance –

- Smart Fan

- Smart Lights

- Smart Window

- Smart AC

- Smart Door

Working of the Smart Warehouse Using Cisco Packet Tracer and IoT Devices

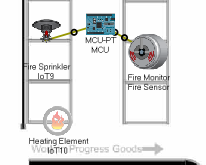

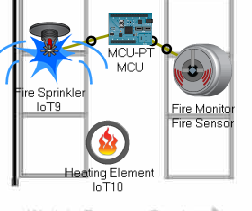

The Smart Warehouse project leverages IoT technology to create an automated, secure, and efficient storage environment. The system integrates multiple IoT devices connected via a central gateway, allowing real-time monitoring and control. The first key functionality is the fire detection and extinguishing system. A fire sensor continuously monitors the warehouse for any signs of fire. Upon detection, it sends a signal to the microcontroller unit (MCU), which triggers the sprinkler system to extinguish the fire before it causes significant damage. This ensures worker safety and minimizes product loss [4] [5].

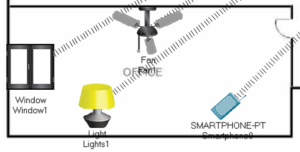

The second functionality focuses on enhancing the quality of life for workers through smart appliances like lights, fans, and windows. These devices are connected to a smartphone via a gateway, enabling remote control. Workers can adjust lighting, ventilation, and temperature settings effortlessly, improving comfort and energy efficiency.

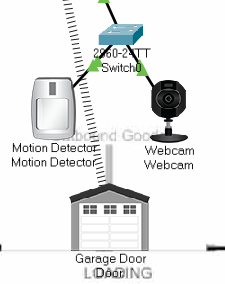

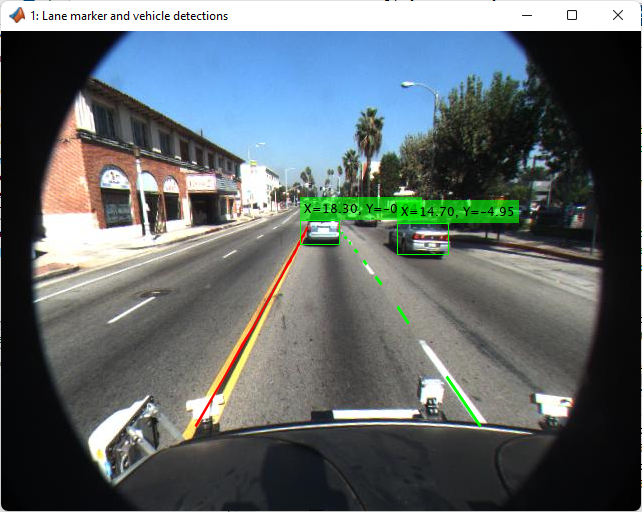

The third aspect is security enhancement, achieved using motion sensors, webcams, and smart doors. When the motion sensor detects movement, it activates the webcam to record footage, ensuring surveillance. The smart door, also linked to the gateway, can be controlled remotely via the smartphone, allowing authorized access while preventing unauthorized entry [6] [7].

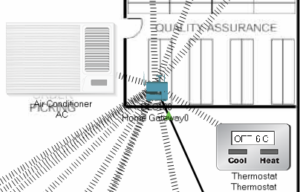

The fourth functionality ensures optimal storage conditions for products by maintaining a regulated temperature. A thermostat continuously monitors the warehouse temperature and communicates with the smart AC via the gateway. If the temperature deviates from the set range, the AC adjusts automatically, preserving product quality.

By integrating these IoT-based automated systems, the Smart Warehouse improves worker safety, security, and product storage conditions while reducing manual intervention. The project, simulated in Cisco Packet Tracer, demonstrates how IoT can transform traditional warehouses into intelligent, efficient, and secure environments [10].

Complete Layout of the Smart Warehouse

First functionality is the fire sense and fire extinguishers system. Fire is sensed by fire sensor then it passed the signal to connected MCU and then MCU passed the signal to the sprinkler to extinguish the fire before any damage caused [8].

You can download the Project files here: Download files now. (You must be logged in).

Second Functionality is to make quality of life better and easier by using of appliances such as smart fan, smart light and smart window which can be controlled by a smart phone which is connected to a gateway which control all the appliances.

Third functionality is for improving the security measure by using motion sensor, webcam and a automatic smart door.Webcam start recording once motion sensor sense any motion around it and a smart door is connected with the same smart phone which is connected to same gateway discussed above to control the movement of door accordingly [9].

Fourth functionality is to maintain the quality of the product stored inside the warehouse by controlling the temperature inside the warehouse.A thermostat is used for monitoring the temperature continuously which is connected to a same gateway discussed above and a smart ac is also connected to it which is used to control the temperature accordingly.

Conclusion

A real time Smart Warehouse using IOT system is developed using CISCO Packet Tracer to improve the safety of the worker working inside the warehouse and improve the quality and security of the product stored inside the warehouse. The Smart Warehouse using Cisco Packet Tracer and IoT devices demonstrates how automation and IoT technology can revolutionize traditional warehouse management. By integrating fire sensors, motion detectors, smart lighting, climate control, and security systems, the project ensures enhanced worker safety, improved product quality, and robust security. The system operates autonomously, reducing human intervention while optimizing energy usage and operational efficiency. The simulation in Cisco Packet Tracer validates the feasibility of deploying IoT in real-world warehouses, offering a scalable and cost-effective solution for industries. Future enhancements could include AI-based predictive maintenance, RFID-based inventory tracking, and cloud-based remote monitoring for even smarter warehouse management.

References

- Atzori, L., Iera, A., & Morabito, G. (2010). The Internet of Things: A survey. Computer Networks, 54(15), 2787-2805.

- Gubbi, J., Buyya, R., Marusic, S., & Palaniswami, M. (2013). Internet of Things (IoT): A vision, architectural elements, and future directions. Future Generation Computer Systems, 29(7), 1645-1660.

- Cisco Systems. (2021). Cisco Packet Tracer: Network Simulation Tool. [Online] Available: https://www.netacad.com/courses/packet-tracer

- Zanella, A., Bui, N., Castellani, A., Vangelista, L., & Zorzi, M. (2014). Internet of Things for Smart Cities. IEEE Internet of Things Journal, 1(1), 22-32.

- Vermesan, O., & Friess, P. (Eds.). (2013). Internet of Things: Converging Technologies for Smart Environments and Integrated Ecosystems. River Publishers.

- Lee, I., & Lee, K. (2015). The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Business Horizons, 58(4), 431-440.

- Al-Fuqaha, A., Guizani, M., Mohammadi, M., Aledhari, M., & Ayyash, M. (2015). Internet of Things: A Survey on Enabling Technologies, Protocols, and Applications. IEEE Communications Surveys & Tutorials, 17(4), 2347-2376.

- Wortmann, F., & Flüchter, K. (2015). Internet of Things: Technology and Value Added. Business & Information Systems Engineering, 57(3), 221-224.

- Sundmaeker, H., Guillemin, P., Friess, P., & Woelfflé, S. (2010). Vision and Challenges for Realising the Internet of Things. European Commission.

- Rayes, A., & Salam, S. (2017). Internet of Things From Hype to Reality: The Road to Digitization. Springer.

You can download the Project files here: Download files now. (You must be logged in).

Keywords: Smart Warehouse, CISCO Packet Tracer, IOT devices

Do you need help with Cisco Packet Tracer? Don’t hesitate to contact our Tutors to receive professional and reliable guidance.

Responses