Product Lifecycle Management: 2025 Deep Dive

In 2025, Product Lifecycle Management (PLM) has solidified its role as the strategic backbone of innovation-driven enterprises. Additionally, connecting ideation, design, production, service, and end-of-life processes into a unified “digital thread”. That accelerates time-to-market, ensures regulatory compliance, and drives sustainability initiatives.

Originating in 1985 at American Motors Corporation under François Castaing’s vision for using CAD and centralized data to speed Jeep development. Also, PLM has evolved into a mature, $34.7 billion market in 2024 — projected to reach $59.5 billion by 2030 at a 9.4% CAGR — serving industries from automotive and aerospace to high-tech and consumer goods.

Today’s landscape is dominated by a handful of vendors — Dassault Systèmes, Siemens, PTC, Autodesk, SAP, Oracle, and Aras. They collectively command over 85% of a market that reached $28.4 billion in 2023. Meanwhile, manufacturers such as BMW, Volvo, Jaguar Land Rover, BAE Systems, and NASA leverage PLM to manage complexity, enhance quality, and adopt forward-looking trends like digital twins, generative AI, and cloud-native architectures.

What Is Product Lifecycle Management?

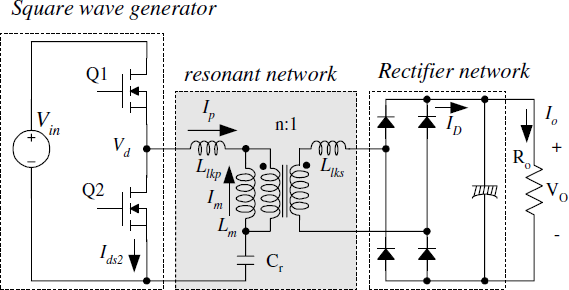

Product Lifecycle Management is the integrated suite of processes, methodologies, and technologies used to manage a product’s lifecycle. At its core, Product Lifecycle Management provides a single source of truth for product-related data. For example, CAD files, bills of materials (BOMs), engineering change orders, and regulatory documentation. That’s enabling real-time collaboration across global teams. By establishing a cohesive digital thread, PLM reduces errors, accelerates decision-making, and fosters innovation.

A Brief History: From Jeep Cherokee to Enterprise Backbone

The genesis of PLM can be traced to 1985 at AMC, where François Castaing introduced CAD systems and centralized data repositories. That helped streamline the development of the Jeep Cherokee and Grand Cherokee. Additionally, slashing development costs and timelines in an era dominated by manual processes. After Chrysler’s acquisition of AMC, these practices were scaled enterprise-wide, laying the groundwork for modern PLM platforms. That now support billions of transactions annually across industries.

Early Adopters and Breakthrough Products

- Jeep Cherokee XJ (1985): First major model to leverage CAD/PDM at AMC, cutting iteration cycles in half.

- Jeep Grand Cherokee: Continued evolution under Chrysler’s enterprise PLM rollout.

- Ford’s PAG Platforms: Later, Ford Group’s Premium Automotive Group (PAG) standardized PLM for Jaguar Land Rover and Volvo before their spinoffs in 2009.

Market Leaders: Software, Tools, and Platforms

The PLM software market is highly concentrated, with the top 10 vendors controlling 85,7% of the market as of 2023. Key players include:

- Dassault Systèmes (3DEXPERIENCE, ENOVIA, CATIA): Leading with 17,1% share, widely used in aerospace, automotive, and luxury goods for end-to-end product development.

- Siemens Digital Industries (Teamcenter): Deep CAD, simulation, and manufacturing integration; holds ~1,4% share among PLM tools and competes across 66 platforms.

- PTC (Windchill, Arena PLM): Known for IoT and AR features; dominant in electronics and high-tech sectors, with major adoption in the U.S., Germany, and India.

- Autodesk (Fusion 360 Manage): Cloud-native PLM ideal for mid-sized manufacturers; emphasizes rapid deployment and collaborative workflows.

- SAP (SAP PLM): Seamlessly integrated with SAP ERP for regulated industries; offers robust engineering change management and compliance modules.

- Oracle (Agile PLM): Strong in workflow automation and regulatory compliance, used extensively in electronics and life sciences.

- Aras (Innovator): Open-source, low-code platform with ~1,69% share; experienced 50% YoY growth in SaaS deployments in 2023. Despite these modest percentages, Aras Innovator has demonstrated significant growth and industry recognition. In the first three quarters of 2023, Aras experienced over 50% year-over-year growth in SaaS deployments for its Aras Innovator platform. Additionally, Aras was named the 2023 technology leader in Quadrant Knowledge Solutions’ SPARK Matrix™ for Product Lifecycle Management, highlighting its strong ratings in technology excellence and customer impact.

Major Industries and Corporate Adopters

Automotive

BMW, Volvo, and Jaguar Land Rover turned to PLM early on to tame the complexity of designing, manufacturing, and customizing global vehicle platforms.

- BMW maintains a multi-system PLM landscape: Teamcenter handles CAD data management, SAP PLM the engineering Bill of Materials (eBOM), and PTC Windchill the manufacturing BOM (mBOM) and conversion workflows. This “three-pillar” strategy allowed BMW to retire legacy mainframes and accelerate global production planning, with Windchill serving as the digitization backbone for BOM configuration and release.

- Jaguar Land Rover spun off from Ford’s Premier Automotive Group in 2008 and began piloting Dassault Systèmes’ 3DEXPERIENCE for CAD, PDM, and collaboration. By 2014, JLR positioned itself as the reference case for ENOVIA, aiming to consolidate multiple legacy data silos into a unified PLM platform.

- Volvo likewise separated from Ford’s EUCD platform lineage and adopted Siemens Teamcenter integrated with CATIA for global design and BOM management. These PLM systems underpin models from the S60 to the XC90, ensuring variant control and compliance across production sites.

Aerospace & Defense

In aerospace and defense, PLM systems provide rigorous configuration control, traceability, and digital simulation capabilities:

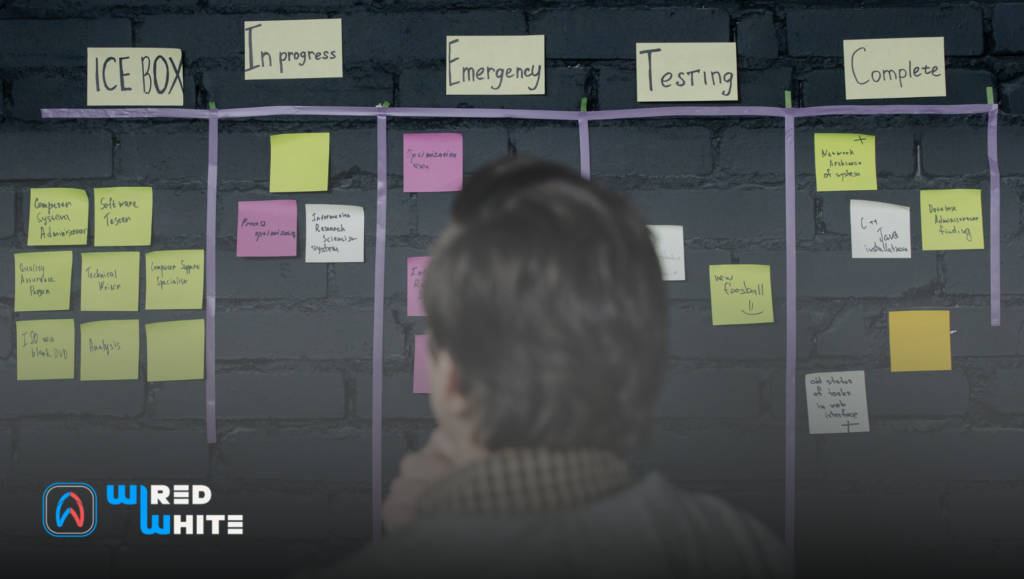

- BAE Systems employs a model-based engineering approach — leveraging digital twins and integrated CAD/CAE workflows — to plan complex defense platforms. The company credits PLM with enabling synthetic testing and virtual assembly, reducing physical prototyping and accelerating delivery.

- NASA’s Jet Propulsion Laboratory used Siemens PLM (Teamcenter and NX) to design, simulate, and assemble the Curiosity Mars rover entirely in digital form before building any physical prototypes. This approach cut manual rework, improved configuration management, and compressed development schedules by nearly 40%.

High-Tech & Consumer Goods

PLM’s reach extends beyond heavy industry into consumer and electronics manufacturing:

- Philips uses PLM to align global R&D, manufacturing, and regulatory compliance, ensuring that healthcare devices from concept to post-market surveillance maintain a single source of truth .

- Honeywell integrates Teamcenter and Windchill to manage complex product portfolios — ranging from aviation components to building automation—streamlining variant management and engineering change processes .

- Electrolux deploys Fusion Lifecycle (Autodesk) for cloud-native PLM, empowering mid-sized manufacturing teams with rapid deployment and collaborative design review features across its global appliance lines.

WiredWhite’s Role in Product Lifecycle Management

Here’s how WiredWhite’s platform tools — and the additional tools you’ve built — map to a complete PLM vision:

1. Requirements Management

Project Management Tool (Kanban & Task Planning): Capture stakeholder needs as epics or stories in your in-house Kanban board. Early validation checkpoints (review meetings, sign‐off tasks) ensure requirements traceability and reduce rework.

2. CAD Integration

File Management Tool: All CAD files, drawing revisions, and associated metadata live in a centralized, version-controlled repository. Access controls and audit logs (QS compliance) guarantee that every design artifact is traceable and secure.

3. BOM & Part Master Management

Project Management Tool: Multi‐level BOM authoring workflows (create, review, approve) are tracked as tasks or checklist items. You can link each BOM line to a task or milestone, ensuring visibility of part-level responsibilities.

File Management Tool: Store and manage part specifications, compliance certificates, and supplier documentation alongside your BOM so that audit trails are complete.

4. Change & Configuration Management

Chat Messenger & Video Conferencing: When an engineering change request arises, teams can kick off an immediate synchronous review (screenshare + meeting recording for audit) to discuss impact and scope. Recorded sessions feed directly into the audit trail for compliance.

Project Management Tool: Automated “Change Order” cards trigger predefined workflows (impact analysis, approval gates, release tasks), ensuring every revision is managed programmatically.

5. Collaborative Workspaces

Chat Messenger & Video Conferencing: Real-time channels (text, voice, video) keep cross-functional teams aligned; session recordings provide a searchable history of decisions.

File Management Tool: Shared document libraries and living requirements/design documents become the single source of truth.

6. eLearning LMS

Embed training modules — on new product introductions, compliance updates, or process changes — directly into the PLM workflow. Assign “completion” as a gating requirement before certain configuration tasks can proceed, closing the loop on knowledge transfer and audit readiness.

Note on SLM Features

While WiredWhite covers the core PLM domains, full Service Lifecycle Management (SLM) usually adds:

- Service BOM Management

- Field Service Operations & Logistics

- Warranty Registration & Tracking

You can roadmap these into future modules or integrate best-of-breed SLM tools alongside WiredWhite. As a result, closing the loop from in-service maintenance back to design and change management.

Trends & Forecast: The Next Wave of Innovation

- Market Growth: From $34,7 billion in 2024 to an expected $59,5 billion by 2030 (9,4% CAGR).

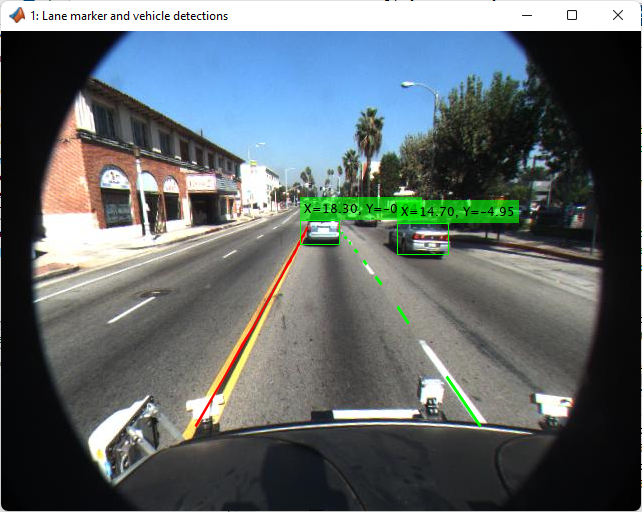

- Digital Twins & Closed-Loop Systems: Companies embedding IoT sensors into products to create live digital twins. Basically, enabling predictive maintenance and sustainable design.

- Generative AI & Automation: AI-driven part suggestion, automated documentation, and intelligent design optimization reduce engineering workload by up to 30%.

- Cloud-Native PLM: Rapid shift to SaaS and cloud architectures (Teamcenter X, Fusion 360 Manage). As a result, lowering IT overhead and speeding global deployment.

- Sustainability & Compliance: Lifecycle data leveraged to track carbon footprints, material compliance, and circular-economy metrics. As can be seen, that’s driven by regulations like the EU’s Ecodesign for Sustainable Products Regulation.

Service Lifecycle Management (SLM): Complementing PLM

Service Lifecycle Management (SLM) addresses the post-sale phases—field service, warranty, spare-parts logistics, and reverse-logistics—to maximize asset uptime and customer satisfaction.

- Definition: According to IFS, SLM is “the holistic process of service from request to delivery to maximize value over the life of a product or asset”. As a result, encompassing resource coordination, service offerings, and execution workflows.

- Key Functions: SLM platforms manage service BOMs, work orders, parts and inventory, technical communications, and knowledge bases. Accordingly, proper SLM ensures that service teams have the right parts, information, and scheduling to resolve issues quickly.

- Industry Example: Syncron’s AI-powered SLM platform unifies pricing, inventory optimization, and warranty management. That helps to to transform aftermarket services into a competitive advantage for manufacturers such as Caterpillar, Ford, and Komatsu.

- PLM vs. SLM: Another key point, Product Lifecycle Management orchestrates product development workflows — from concept through disposal. SLM focuses on the operational lifecycle, managing maintenance, field deployments, and reverse logistics. All in all, they form a closed-loop system: insights from service feedback into product design for continuous improvement.

By 2025, leading enterprises across automotive, aerospace, and consumer goods have demonstrated that robust PLM adoption drives innovation, quality, and speed to market. Meanwhile, SLM ensures those products remain operational and profitable long after roll-out. Finally, the convergence of these disciplines will define the next era of product and service excellence.

Responses