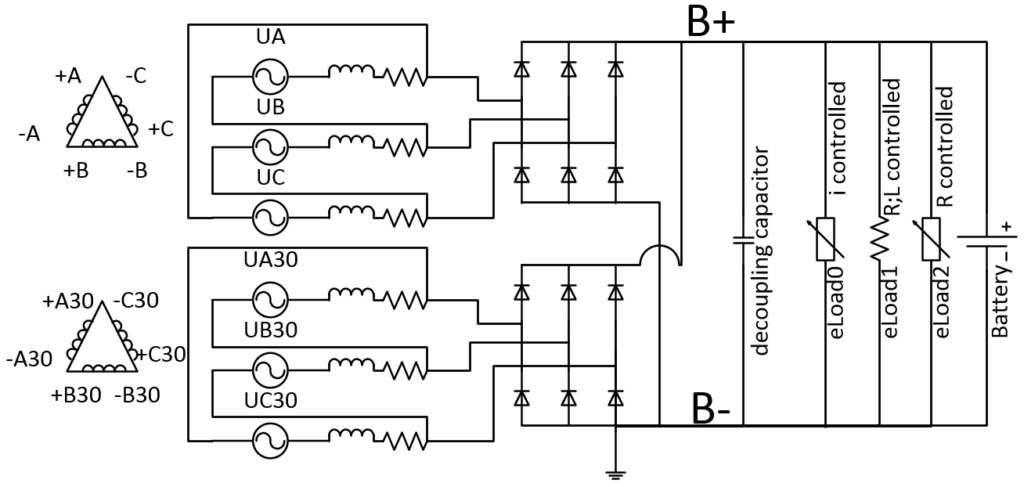

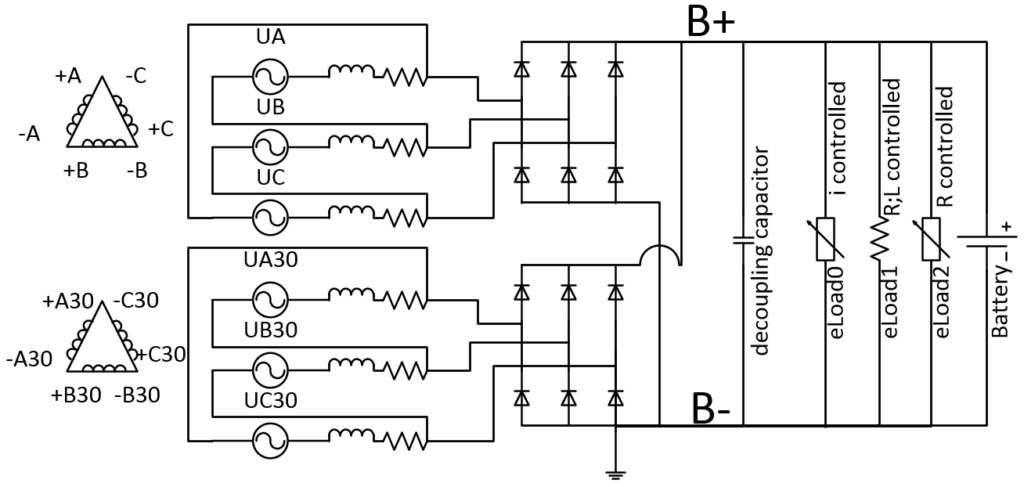

Modeling and Simulation of Vehicle Power Network in Simulink MATLAB

Modeling and Simulation of Vehicle Power Network in Simulink MATLAB

Modeling and Simulation of Vehicle Power Network in Simulink MATLAB

Please confirm you want to block this member.

You will no longer be able to:

Please allow a few minutes for this process to complete.