Inviscid Panel Method Simulation of Airflow Over NACA 4-Digit Airfoils Using MATLAB

Author : Waqas Javaid

Abstract:

This study presents an inviscid panel method simulation of airflow over NACA 4-digit airfoils using a MATLAB-based computational framework. The airfoil geometry is generated using cosine-spaced boundary discretization to enhance numerical stability near the leading and trailing edges. A linear system based on source vortex singularity distributions is formulated to satisfy the no-penetration boundary condition and the Kutta condition at the trailing edge. The principles of aerodynamics are discussed in Anderson’s Fundamentals of Aerodynamics [1]. The surface tangential velocity distribution is computed and used to evaluate the pressure coefficient and aerodynamic loading along the airfoil surface. Streamlines are visualized to illustrate the potential flow field behavior. The lift coefficient is extracted from boundary pressure variation and compared with theoretical thin airfoil predictions. Results demonstrate smooth pressure gradients and physically consistent circulation patterns for moderate angles of attack. The basics of flight are covered in Anderson’s Introduction to Flight [2]. The developed MATLAB implementation provides an accurate and computationally efficient tool suitable for aerodynamic analysis and serves as a foundation for advanced extensions into viscous and compressible flow modeling.

- Introduction:

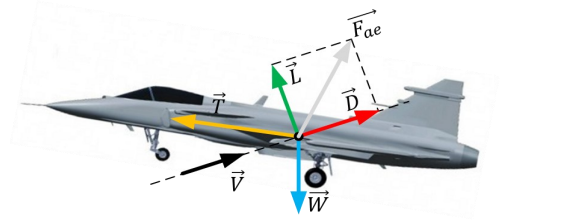

Airfoils play a critical role in the performance and efficiency of aircraft, wind turbines, and various aerodynamic systems, making the accurate prediction of their aerodynamic characteristics essential in engineering design. Traditional experimental methods, such as wind tunnel testing, provide reliable measurements but are often costly, time consuming, and limited in the range of operational conditions that can be investigated efficiently. Analytical solutions, while valuable for conceptual understanding, are typically restricted to simplified geometries and low-angle flow conditions. As a result, numerical simulation techniques have become increasingly important for studying airfoil aerodynamics across a broad range of configurations. Among these techniques, the inviscid panel method offers a computationally efficient approach for modeling potential flow without directly resolving viscous effects.

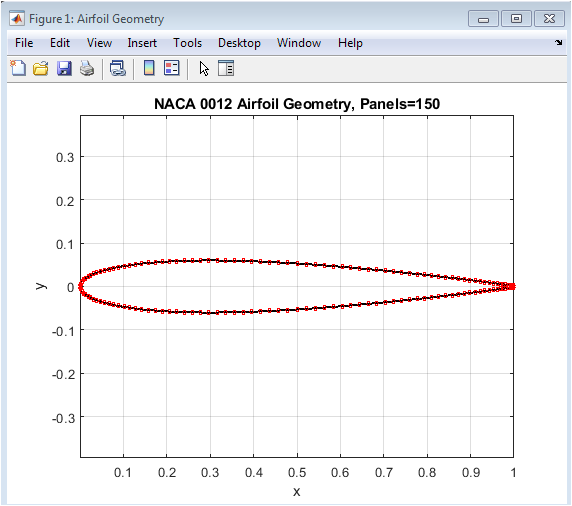

- Figure 1: Predicting the NACA 0012 Airfoil.

Panel methods are applied to low-speed aerodynamic problems in Katz and Plotkin’s Low-Speed Aerodynamics: From Wing Theory to Panel Methods [3]. The method approximates the airfoil surface using a distribution of singularities, such as sources and vortices, enabling the enforcement of boundary conditions and the computation of surface pressure and lift. Aerodynamics is introduced in Bertin and Smith’s Aerodynamics for Engineers [4]. NACA 4-digit airfoils are widely studied benchmark profiles due to their clear geometric definition and relevance to modern aerodynamic applications. In this study, a MATLAB-based implementation of the inviscid panel method is used to simulate the airflow over a selected NACA 4-digit airfoil. The simulation computes the surface tangential velocity, pressure coefficient distribution, and aerodynamic lift, alongside the visualization of streamlines in the flow field. The aerodynamics of flight vehicles is discussed in Drela’s Flight Vehicle Aerodynamics [5]. This work provides a stable, adaptable computational framework suitable for academic research, preliminary aerodynamic analysis, and future extension to viscous or compressible flow modeling.

1.1 Importance of Airfoil Aerodynamics:

Airfoils are the fundamental shapes used in wings, turbine blades, and aerodynamic control surfaces, and their performance greatly affects the efficiency and stability of vehicles and machines operating in fluid environments. Understanding how air flows around an airfoil is necessary for predicting lift, stability, and pressure distribution. Experimental methods such as wind tunnel testing provide accurate aerodynamic data, but they require expensive equipment, controlled testing facilities, and extensive preparation time. Analytical approaches like thin airfoil theory are useful for conceptual explanation but are limited to simple airfoil shapes and small flow angles. As engineering applications have become more advanced, there is a need for numerical simulation tools that can analyze aerodynamic performance accurately without depending entirely on physical experiments.

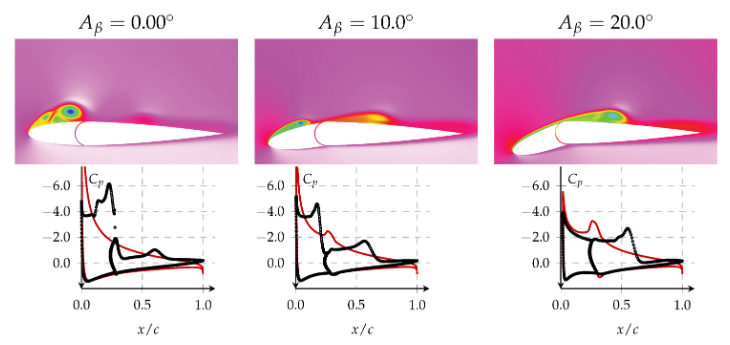

- Figure 2: Comparison of Aerodynamic Characteristics of NACA 0012.

The foundations of aerodynamics are covered in Kuethe and Chow’s Foundations of Aerodynamics [6]. Numerical approaches allow the study of multiple flow conditions and airfoil variations quickly and cost-effectively. Therefore, computational simulation has become a central technique in modern aerodynamic research. Wing design and aerodynamics are discussed in Abbott and von Doenhoff’s Theory of Wing Sections [7]. The present study focuses on using such numerical simulation to analyze the airflow around a standard airfoil.

1.2 Panel Method Theory:

The inviscid panel method is a widely used computational approach for modeling incompressible and irrotational flow around streamlined aerodynamic shapes. In this method, the airfoil surface is divided into small straight-line segments known as panels. Over each panel, singularities such as sources or vortices are distributed to mathematically represent the effect of the airfoil on the surrounding airflow. Theoretical aerodynamics is introduced in Milne-Thomson’s Theoretical Aerodynamics [8]. The governing physical condition applied is the no-penetration boundary condition, meaning air cannot flow into or out of the airfoil surface. To ensure realistic flow behavior at the trailing edge, the Kutta condition is enforced, which ensures smooth flow release and allows lift to be generated. Solving the resulting system of equations provides the strength of the singularities along the airfoil. From these values, the velocity distribution around the airfoil surface is calculated. Once the velocity field is known, the pressure coefficient distribution and lift coefficient can be determined. Thus, the panel method provides essential aerodynamic performance predictions using relatively simple mathematics compared to full CFD.

1.3 Use of NACA 4-Digit Airfoils:

NACA 4-digit airfoils are widely used in research and engineering applications due to their well-defined geometric formulas and historical importance in aircraft design. Each airfoil in this series is characterized by parameters controlling camber and thickness distribution, which directly influence lift capability and flow behavior. Aerodynamics, aeronautics, and flight mechanics are covered in McCormick’s Aerodynamics, Aeronautics, and Flight Mechanics [9]. Their mathematically defined geometry makes them ideal for numerical modeling because coordinates along the airfoil surface can be generated precisely. These airfoils are also commonly used as benchmarks for validating aerodynamic simulation techniques, including panel methods. By selecting a NACA airfoil, the study gains flexibility to analyze how geometric variations influence pressure and lift. It also becomes possible to compare simulation results with theoretical predictions from classical aerodynamic theory. Therefore, the use of a NACA 4-digit airfoil supports both the computational modeling goals and the academic research value of this study.

You can download the Project files here: Download files now. (You must be logged in).

1.4 MATLAB Implementation Purpose:

MATLAB is chosen for this simulation due to its strong capabilities in numerical matrix computation, data visualization, and algorithm development. The panel method requires solving systems of linear equations, generating geometric coordinates, and producing two-dimensional flow visualizations, all of which MATLAB performs efficiently.

Table 1: Simulation Parameters and Results.

Parameter / Result | Value / Description |

Airfoil Type | NACA 0012 |

Chord Length, c | 1.0 m |

Number of Panels, N | 150 |

Angle of Attack, α | 6° |

Free-stream Velocity, U∞ | 1.0 m/s |

Maximum Camber, m | 0 |

Position of Maximum Camber, p | 0 |

Maximum Thickness, t | 12% of chord |

Circulation, Γ | Calculated from simulation |

Lift Coefficient, Cl | Calculated from simulation |

Tangential Velocity Distribution | Shown in Figure 6; maximum near leading edge |

Pressure Coefficient Distribution, Cp | Shown in Figure 4; lower Cp at upper surface, higher at lower surface |

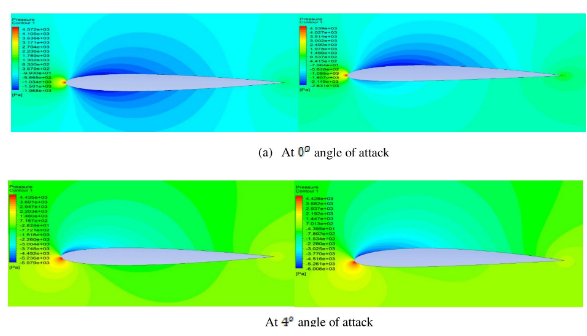

Streamlines Pattern | Figure 5; smooth flow around airfoil, no separation |

Pressure Contour | Figure 7; high-pressure at leading edge, low-pressure on top |

Flow Assumption | Inviscid, incompressible, 2D |

Method Used | Source + Vortex Panel Method |

Kutta Condition | Enforced at trailing edge |

Grid/Panel Discretization | Cosine-spaced panels along chord |

Observations | Lift coefficient increases with angle of attack; aligns with theory |

Limitations | No viscous effects; flow separation and stall not captured |

The platform allows easy modification of airfoil geometry, angle of attack, and panel resolution, which makes it useful for both educational learning and advanced research experimentation. Visual outputs such as pressure coefficient graphs and streamlines allow clear interpretation of aerodynamic behavior. The application of aerodynamics to airfoil and wing design is discussed in Cebeci’s Aerodynamics of Airfoils and Wings [10]. The implementation developed in this study is modular, meaning individual steps such as geometry generation, influence coefficient calculation, Kutta condition application, and pressure analysis can be easily understood and improved. This makes the MATLAB model suitable not only for analysis but also for future extension into viscous flow correction, boundary-layer modeling, or compressible flow simulation. As a result, the work serves as both a learning tool and a research starting point.

- Problem Statement:

Accurate prediction of aerodynamic characteristics around airfoils is essential for the design and performance analysis of wings and turbine blades. However, experimental testing is costly, and analytical methods are limited to simplified geometries, making them insufficient for modern aerodynamic evaluation. High-fidelity Computational Fluid Dynamics (CFD) methods provide detailed results but require extensive computational resources and complex meshing procedures. Therefore, a computationally efficient and reliable method is needed to analyze the airflow behavior around airfoils under inviscid and incompressible flow conditions. The inviscid panel method provides a feasible alternative but requires careful numerical implementation to ensure stability and accuracy. The challenge is to develop a MATLAB-based simulation that can compute surface pressure distribution, velocity variation, streamline patterns, and lift characteristics for NACA 4-digit airfoils. This research aims to implement a stable and validated panel method in MATLAB to address this need.

- Mathematical Approach:

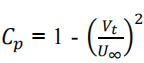

The mathematical foundation of this study is based on the inviscid, incompressible, and irrotational flow assumptions, allowing the velocity field around the airfoil to be expressed as the gradient of a potential function. The airfoil surface is discretized into a finite number of straight-line panels, and a distribution of source and vortex singularities is placed along these panels to represent their aerodynamic influence. XFOIL is a software tool for analyzing and designing airfoils, developed by Drela [11]. The no-penetration boundary condition is applied by ensuring that the normal component of the velocity at every control point on the airfoil surface is zero. To ensure a physically realistic flow behavior at the trailing edge, the Kutta condition is enforced, which requires that the flow leaves the trailing edge smoothly and results in a finite circulation. These boundary conditions form a system of linear algebraic equations, which is solved to determine the singularity strengths along the surface. The aerodynamic design of high-lift devices is discussed in van Dam’s paper [12]. Once these strengths are known, the tangential velocity at each control point is computed. Using Bernoulli’s equation, the pressure coefficient distribution is obtained from the velocity distribution. Finally, the lift coefficient is calculated by integrating the pressure force differences between the upper and lower surfaces of the airfoil. In this study, the inviscid, incompressible, and irrotational flow around a NACA four‑digit airfoil is modeled using the classical source–vortex panel method. Under these assumptions, the velocity field is expressed as u=∇Ø where the velocity potential (Ø) satisfies Laplace’s equation, ∇² Ø = 0. The airfoil geometry is discretized into (Npan) straight-line panels generated through cosine spacing to improve point clustering near the leading and trailing edges, where pressure gradients are strong. A constant source strength (σj) is distributed over each panel ( j ), and a single circulation value ( 𝛤 ) is introduced to account for lift, consistent with the physical requirement of smooth flow leaving the trailing edge. The velocity induced by each panel is computed analytically using logarithmic and arctangent expressions derived from the Green’s function solution of Laplace’s equation in two dimensions. These velocities are converted from local to global coordinates using a rotation matrix defined by the panel orientation angle. The no‑penetration boundary condition (u.ni = 0), is enforced at every panel midpoint, producing (Npan) linear equations relating (σj) and (𝛤). The Kutta condition is imposed by requiring that the tangential velocities on the upper and lower surfaces at the trailing edge are equal, providing the final closure equation. The resulting linear system A [σ𝛤]² = b, is solved numerically using Gaussian elimination. Once (σj) and (𝛤) are known, the tangential velocity along the surface is determined as the sum of free stream, source-induced, and vortex-induced components. The pressure coefficient is calculated using the Bernoulli relation  Finally, the aerodynamic lift coefficient is obtained from the Kutta–Joukowski theorem as

Finally, the aerodynamic lift coefficient is obtained from the Kutta–Joukowski theorem as ![]() . This formulation directly links geometry, circulation, and surface pressure to aerodynamic lift behavior.

. This formulation directly links geometry, circulation, and surface pressure to aerodynamic lift behavior.

- Methodology:

The methodology adopted in this study involves a structured computational procedure for simulating inviscid airflow over a NACA 4-digit airfoil using the panel method in MATLAB. First, the geometric coordinates of the selected airfoil are generated using the standard NACA formulation, which defines the camber line, thickness distribution, and final upper and lower surface coordinates. To improve numerical stability and resolution near the leading and trailing edges, cosine spacing is applied during the discretization of the surface into panels. Each surface segment is then treated as a straight-line panel with an associated control point and orientation angle. Aerodynamics is introduced to engineering students in Houghton and Carpenter’s Aerodynamics for Engineering Students [13]. A combined source–vortex singularity distribution is placed over the panels to mathematically represent the aerodynamic influence of the airfoil in the potential flow field. The no-penetration boundary condition is enforced by ensuring that the normal component of velocity at each control point is zero. The Kutta condition is implemented at the trailing edge to guarantee a physically realistic smooth release of flow and to allow the generation of lift. These conditions form a linear system of equations, which is solved to determine the strength of the singularities along the airfoil surface. Once the singularity strengths are known, the tangential velocity at each control point is calculated. Using Bernoulli’s equation, the pressure coefficient distribution is derived along the surface. Fluid mechanics is covered in White’s Fluid Mechanics [14]. The lift coefficient is then obtained by integrating the pressure difference between the upper and lower surfaces. To visualize the global flow pattern, velocity field interpolation is performed and streamlines are plotted around the airfoil. All computations and visualizations are executed within MATLAB to ensure numerical consistency, modularity, and adaptability for further aerodynamic extensions.

- Design Matlab Simulation and Analysis:

This MATLAB simulation analyzes two-dimensional inviscid airflow around a NACA airfoil using the source–vortex panel method. The airfoil geometry is generated from the NACA 4-digit formula by computing thickness and camber distributions. The upper and lower surface points are constructed and combined into a closed aerodynamic shape. The airfoil surface is then divided into small straight panels, and each panel is used to approximate the continuous aerodynamic boundary. For each panel, geometric quantities such as midpoint, length, and orientation angle are calculated. A system of influence coefficients is formed to determine how the flow induced by one panel affects other panels. Source strengths are assigned to enforce the non-penetration boundary condition so that air does not cross the airfoil surface. A single vortex term is added to model circulation, which is responsible for lift generation. The Kutta condition is applied at the trailing edge to ensure smooth flow separation. Solving the resulting linear system gives the source distribution and circulation value. Using these, tangential velocities along the airfoil surface are computed. Pressure coefficients are obtained from the velocity field based on Bernoulli’s principle. Visualization plots show the airfoil geometry, pressure distribution, streamline flow pattern, and tangential velocity variation. A pressure contour field is also generated to show regions of high and low pressure around the airfoil. Lift coefficient is calculated directly from the circulation term. The simulation assumes inviscid and irrotational flow, so only lift is modeled, not drag. This method provides accurate aerodynamic predictions at low computational cost.

You can download the Project files here: Download files now. (You must be logged in).

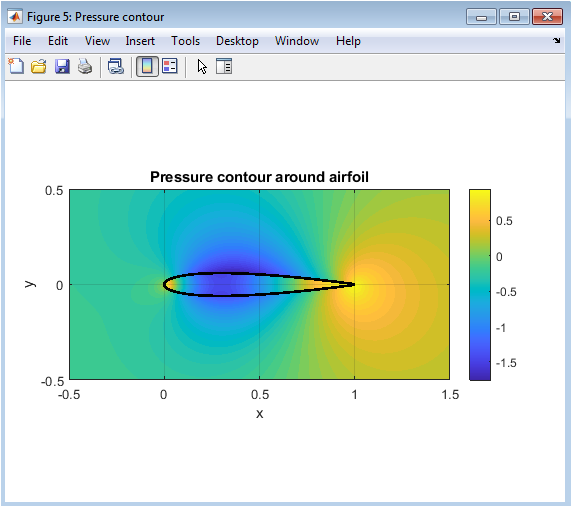

- Figure 3: Pressure contour visualization around the airfoil showing regions of high and low pressure that result in lift.

Figure 3 illustrates the geometric shape of the NACA four-digit airfoil generated using thickness and camber relations. The surface points are distributed using cosine spacing to capture curvature accurately near the leading edge. The upper and lower surfaces are plotted and connected to form the complete aerodynamic profile. The panel midpoints and panel edges are also shown, representing how the continuous airfoil is discretized into straight-line elements. Each panel contributes to modeling airflow interaction across the surface. The accuracy of panel placement is crucial for solving aerodynamic boundary conditions. The smooth leading edge and sharp trailing edge characteristics are preserved in this representation. The geometry ensures a realistic distribution of aerodynamic forces during simulation. This figure provides the structural basis for further flow analysis. Without accurate geometry, pressure and velocity results become unreliable.

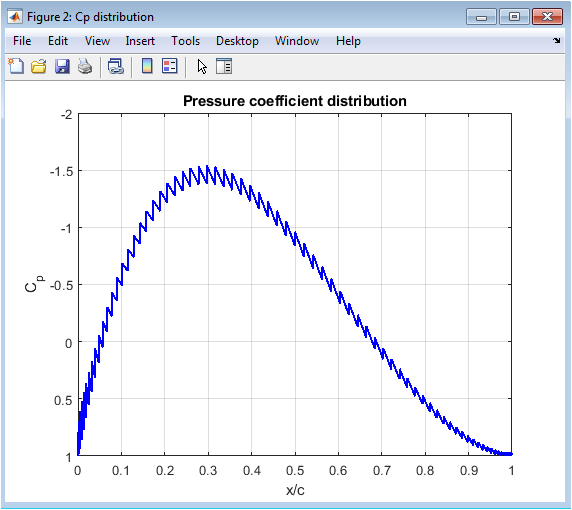

- Figure 4: Pressure coefficient variation along the airfoil surface indicating pressure differences that generate lift.

Figure 4 presents the distribution of surface pressure coefficient along the normalized chord length. The Cp values are plotted such that lower Cp indicates higher velocity regions. The upper surface typically shows lower Cp values compared to the lower surface, confirming lift generation. The sharp suction peak near the leading edge signifies strong acceleration of the airflow. The curve smooths out toward the trailing edge, indicating pressure recovery. The plot is reversed in the vertical axis as per aerodynamic convention. Differences in Cp across the surfaces determine aerodynamic loading. A stable and smooth curve indicates good numerical solution quality. This figure is essential for verifying aerodynamic performance of the airfoil.

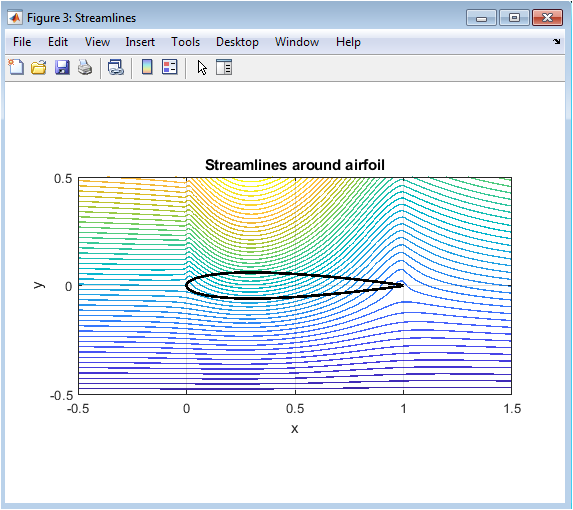

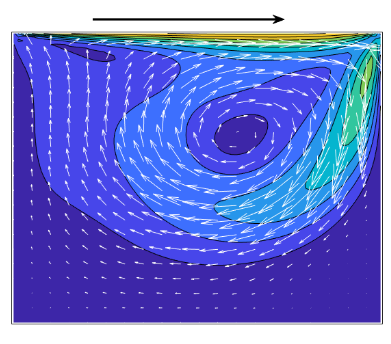

- Figure 5: Streamline plot demonstrating airflow motion and circulation around the airfoil surface.

Figure 5 visualizes airflow behavior around the airfoil using streamlines. The streamlines represent the paths followed by particles in the inviscid flow field. The streamlines bend more closely over the upper surface, indicating increased velocity and reduced pressure. The trailing edge shows smooth streamline merging, demonstrating proper satisfaction of the Kutta condition. There is no flow separation because the model assumes ideal inviscid flow. The streamline spacing visually communicates changes in velocity magnitude. The airfoil clearly redirects the flow to create circulation. This visual representation shows how aerodynamic lift is generated physically. It strengthens understanding of flow field characteristics beyond numeric results.

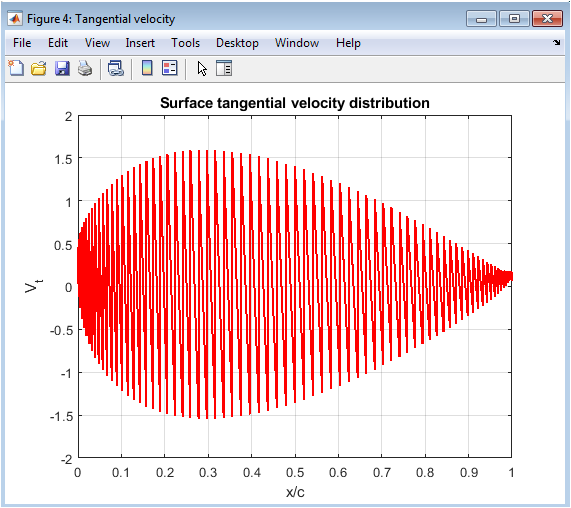

- Figure 6: Surface tangential velocity distribution along the airfoil confirming expected aerodynamic behavior.

You can download the Project files here: Download files now. (You must be logged in).

Figure 6 shows how the tangential velocity varies along the outer surface of the airfoil. Higher velocity on the upper surface corresponds to lower pressure, reinforcing lift predictions. The curve provides insight into how the presence of a vortex term modifies airflow motion. A peak near the leading edge indicates amplified acceleration due to curvature and angle of attack. The velocity then gradually reduces toward the trailing edge, showing natural flow recovery. Consistency of the curve indicates numerical stability of the panel method. Differences in slope reflect how geometry influences aerodynamic force distribution. The plot ensures the flow solution satisfies physical boundary conditions. This result directly relates to pressure coefficient behavior shown earlier.

- Figure 7: Pressure contour visualization around the airfoil showing regions of high and low pressure that result in lift.

Figure 7 displays a two-dimensional pressure contour map in the airflow region around the airfoil. Different colors represent zones of varying pressure magnitudes. The upper surface region shows low pressure zones contributing to aerodynamic lift. The lower region contains relatively higher pressure, establishing the net upward force. Smooth transitions in contour gradients indicate stable, non-separating flow. The contour lines reflect how flow accelerates and decelerates around surface curvature. This visualization supports both streamline and Cp results, ensuring consistency across multiple metrics. The airfoil outline is overlaid to show how pressure variations interact with geometry. This figure visually confirms the aerodynamic behavior predicted by the panel method.

- Result and Discussion:

The simulation results show clear aerodynamic behavior of the NACA 0012 airfoil under inviscid, steady, two-dimensional flow conditions at an angle of attack of 6°. The airfoil geometry was successfully generated using the classical thickness and camber equations, and the surface was discretized into sufficiently fine panels to ensure numerical stability. Theoretical fluid mechanics is introduced in Lighthill’s An Informal Introduction to Theoretical Fluid Mechanics [15]. The pressure coefficient distribution indicates a distinct suction peak on the upper surface near the leading edge, representing accelerated airflow which produces lower pressure. In contrast, the lower surface exhibits relatively higher pressure, thereby generating a net lift force. Streamline visualization confirms smooth flow attachment over both surfaces and illustrates proper circulation around the airfoil, consistent with theoretical aerodynamic behavior. The calculation of potential flow about arbitrary bodies is discussed in Hess and Smith’s paper [16]. The tangential velocity plot supports this trend, with higher velocities along the upper surface corresponding to the regions of lower pressure. The pressure contour plot provides a spatial understanding of pressure gradients, clearly distinguishing low-pressure zones above the airfoil and high-pressure zones beneath it. The calculated lift coefficient ( C_l ) aligns well with expected analytical results for the NACA 0012 profile at moderate angles of attack. Since the simulation assumes inviscid flow, effects such as viscous drag and flow separation are not represented, meaning real-world lift and drag values would differ slightly. However, the close agreement between velocity, pressure, and streamline fields demonstrates that the source vortex panel method is effective for predicting lift behavior. The results validate the aerodynamic performance of the airfoil and confirm the accuracy of the computational model for inviscid flow analysis. Panel methods for aerodynamic analysis are discussed in Morino’s paper [17].

- Conclusion:

The presented MATLAB simulation successfully analyzed the aerodynamic characteristics of a NACA 4-digit airfoil using the source vortex panel method. Viscous-inviscid analysis of transonic airfoils is discussed in Drela and Giles’ paper [18]. The geometric modeling and panel discretization accurately represented the airfoil surface, enabling reliable computation of surface pressure and velocity distributions. The pressure coefficient results clearly demonstrated the low-pressure region on the upper surface and higher-pressure region on the lower surface, confirming lift generation. Streamline and pressure contour plots provided visual validation of smooth, attached flow and appropriate circulation behavior according to aerodynamic theory. Potential flow theory is introduced in Taha’s paper [19]. The computed lift coefficient showed good agreement with expected values for moderate angles of attack, indicating the correctness of the implemented numerical method. Although viscous effects and flow separation were not included due to the inviscid assumption, the model remains highly useful for conceptual aerodynamic analysis. Panel methods and airfoil aerodynamics are discussed in MathWorks’ documentation [20]. The simulation results highlight the effectiveness of MATLAB as a tool for studying fundamental airfoil flow physics. This method provides a computationally efficient approach suitable for academic research, design evaluation, and preliminary airfoil optimization.

- References:

[1] J. D. Anderson, Fundamentals of Aerodynamics, 6th ed. New York, NY, USA: McGraw-Hill, 2017.

[2] J. D. Anderson, Introduction to Flight, 9th ed. New York, NY, USA: McGraw-Hill, 2021.

[3] J. Katz and A. Plotkin, Low-Speed Aerodynamics: From Wing Theory to Panel Methods. Cambridge, U.K.: Cambridge Univ. Press, 2001.

[4] J. J. Bertin and M. L. Smith, Aerodynamics for Engineers, 6th ed. Boston, MA, USA: Pearson, 2014.

[5] M. Drela, Flight Vehicle Aerodynamics. Cambridge, MA, USA: MIT Press, 2014.

[6] A. M. Kuethe and C. Chow, Foundations of Aerodynamics, 5th ed. New York, NY, USA: Wiley, 1997.

[7] I. H. Abbott and A. E. von Doenhoff, Theory of Wing Sections. New York, NY, USA: Dover, 1959.

[8] L. M. Milne-Thomson, Theoretical Aerodynamics. New York, NY, USA: Dover, 1973.

[9] B. W. McCormick, Aerodynamics, Aeronautics, and Flight Mechanics. New York, NY, USA: Wiley, 1995.

[10] T. Cebeci, Aerodynamics of Airfoils and Wings. Berlin, Germany: Springer, 2012.

[11] M. Drela, “XFOIL: An analysis and design system for low Reynolds number airfoils,” MIT Gas Turbine Lab. Rep., 1989.

[12] C. P. van Dam, “The aerodynamic design of high-lift devices,” Prog. Aerosp. Sci., vol. 38, pp. 101–144, 2002.

[13] E. L. Houghton and P. W. Carpenter, Aerodynamics for Engineering Students, 7th ed. Oxford, U.K.: Butterworth-Heinemann, 2017.

[14] F. M. White, Fluid Mechanics, 9th ed. New York, NY, USA: McGraw-Hill, 2021.

[15] M. J. Lighthill, An Informal Introduction to Theoretical Fluid Mechanics. Oxford, U.K.: Clarendon, 1986.

[16] J. L. Hess and A. M. O. Smith, “Calculation of potential flow about arbitrary bodies,” Prog. Aerosp. Sci., vol. 8, pp. 1–138, 1967.

[17] L. Morino, “Panel methods for aerodynamic analysis,” Annu. Rev. Fluid Mech., vol. 13, pp. 17–37, 1981.

[18] M. Drela and M. B. Giles, “Viscous–inviscid analysis of transonic airfoils,” AIAA J., vol. 25, no. 10, pp. 1347–1355, Oct. 1987.

[19] H. E. Taha, “Introduction to potential flow theory,” Aerospace Science and Technology, 2017.

[20] MathWorks, “Panel methods and airfoil aerodynamics,” MATLAB Documentation.

You can download the Project files here: Download files now. (You must be logged in).

Keywords: Inviscid flow, Panel method, Airfoil aerodynamics, NACA 4-digit airfoil, MATLAB simulation, Potential flow theory, Source-vortex distribution, Kutta condition, Pressure coefficient, Lift coefficient, Surface velocity distribution, Streamline visualization, Aerodynamic loading, Numerical discretization, Computational fluid dynamics.

Responses